Search

Search

Search

Search

Halliburton collaborates with customers to drive efficiencies throughout the well lifecycle and help maximize asset value

Contact UsOur teams help operators reach hotter and deeper reservoirs while improving asset performance. We provide products, technologies, and integrated services that reduce development costs and support risk mitigation across low- and high-enthalpy geothermal projects.

Our geothermal portfolio includes:

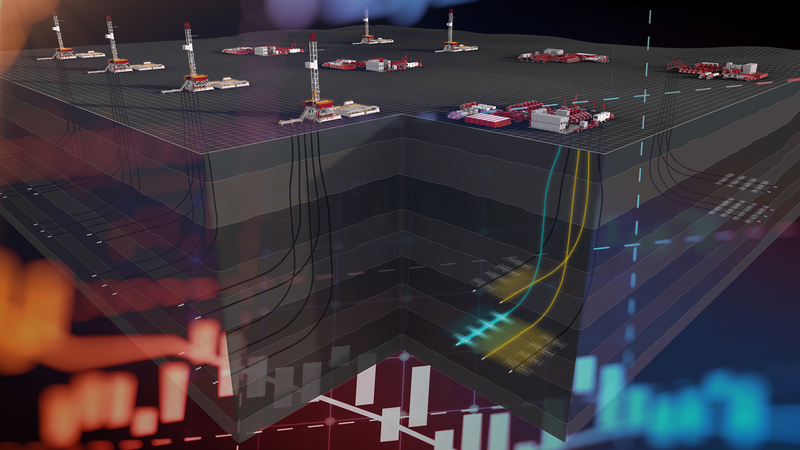

Geothermal wells often require higher upfront investment, making efficient exploration and drilling essential to project economics. Selecting the right service provider can reduce costs, improve drilling success rates, and support broader geothermal development.

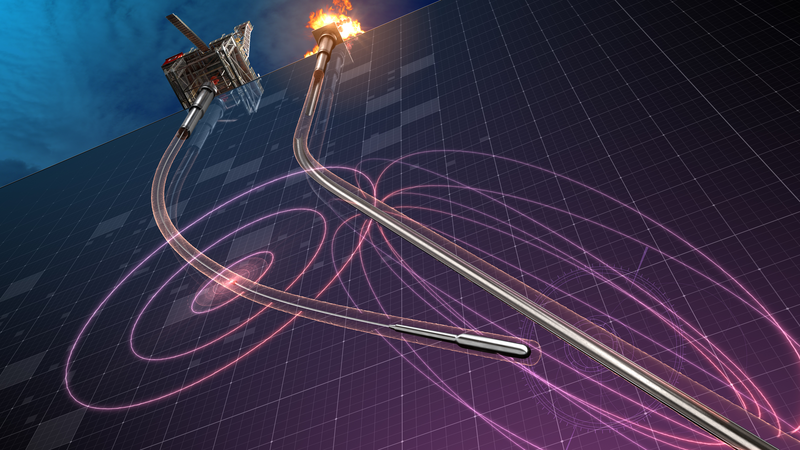

to develop conventional, enhanced, advanced, and direct heating geothermal wells. Our integrated solutions support all four stages of the project lifecycle—from exploration through optimization—to help deliver a lower cost per megawatt.

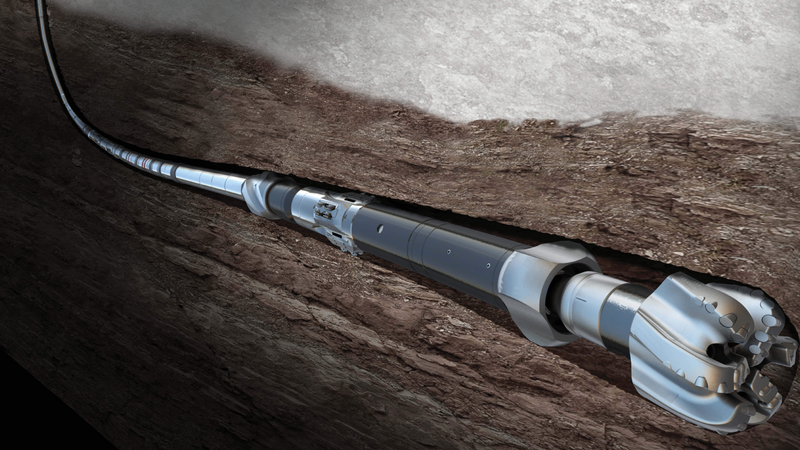

Drilling through hard, corrosive rock and irregular formations demands real-time downhole data, durable tools, and optimized fluid systems. Halliburton provides geothermal drilling solutions that improve rate of penetration and performance in harsh environments.

High temperatures and thermal expansion in geothermal wells can damage the cement, casing, and equipment, resulting in a loss of zonal isolation, gas migration, and eventually, abandonment. Halliburton helps reduce risk for the life of the well by providing engineered solutions that increase wellbore integrity and lower the risk of geothermal well abandonment.

Our drilling fluids, measurement technologies, and additives are designed for extreme geothermal conditions. These systems protect equipment, reduce cement fatigue, and minimize casing collapse.

Halliburton offers integrated services and project management to streamline operations and reduce risk. A single provider model helps improves efficiency and lowers costs through tailored solutions and dedicated teams.

GEOTHERMAL CASE STUDY

GeoESP application redesigned with a wider operating range and covered both wells at half the cost to the customer

read case study

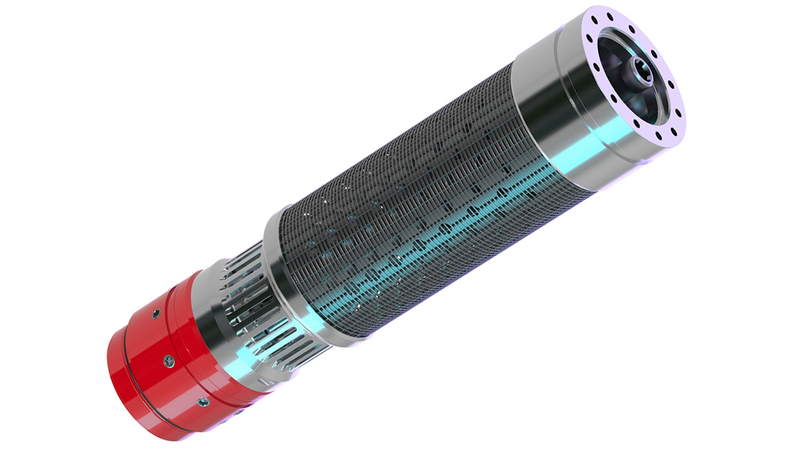

Innovative, modular design seamlessly adapts to a diverse array of pumps and seals, delivering unparalleled solids protection in geothermal applications.

Integrates critical measurements for wellbore placement, drilling performance optimization, and borehole quality.

ThermaLock™ cement is a non-Portland, low permeability barrier system that is nonreactive with CO₂ and is ideal for ultrahigh-temperature applications.

Reliable M/LWD directional data and formation evaluation measurements.

An easy to deploy, cost-effective fracture monitoring solution for continuous measurement and visualization of the subsurface.

The ExpressFiber disposable fiber cable is an economic, low-risk fiber solution for cross-well monitoring that provides direct measurement of well interference.

HydraBlast Pro™ is a slow rotating wash downhole tool with focused high-pressure jetting for scale and organic deposits removal

Expansive portfolio of engineered high-performance water-based fluids and additives that can be customized to meet your specific challenges

Measure, test, and treat high-performance additives with the BaraHib system to help maximize wellbore stability by ensuring effective clay inhibition

Obtain formation pressures and fluid samples in tough environments

WellSpot™ active magnetic-ranging systems use precise sensors to provide data for multiple drilling applications.