Search

Search

Search

Search

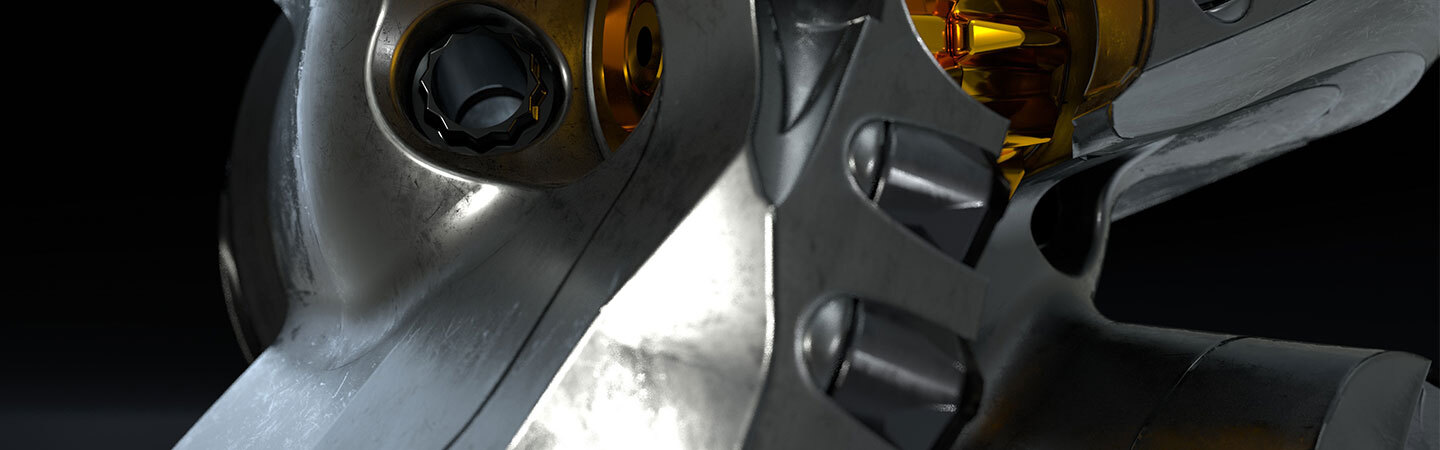

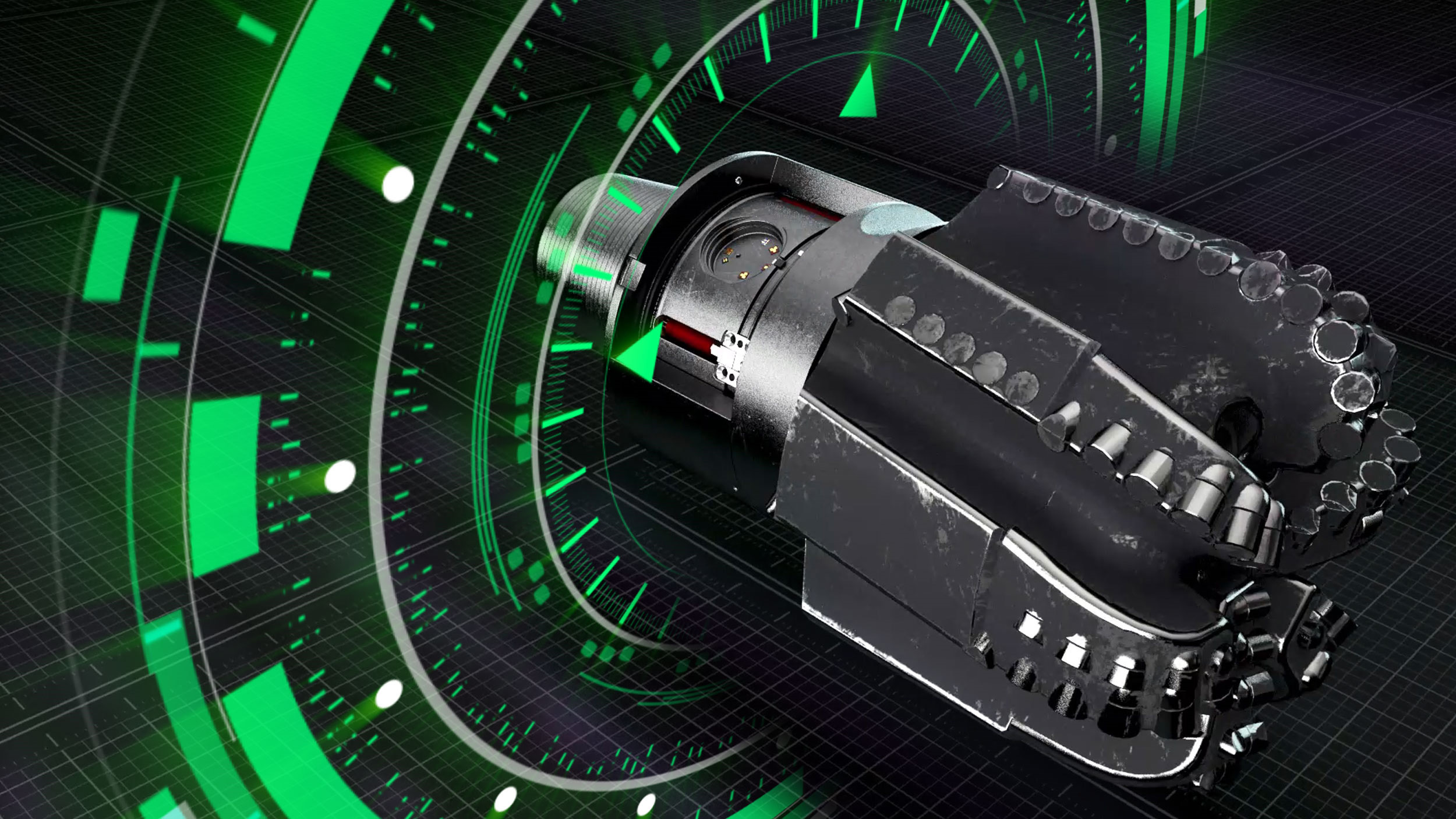

Built on the success of Cerebro® in-bit sensing technology, Cerebro Force™ provides direct, in-bit measurements of weight, torque, bending, vibration, and rotational speed. Utilizing these measurements, along with the Design at the Customer Interface (DatCISM) process, helps reduce or eliminate inefficiencies due to bit design, bottomhole assembly (BHA), and parameter selection.

Cerebro Force in-bit sensing provides the most critical drilling performance measurements at the optimal location within the BHA itself – with zero compromises to the BHA design and with low LIH risk.

case study: the woodford shale

Rapid analysis and recommendations result in significantly prolonged bit life and improved drilling performance.

read case studyData taken from the surface lacks the fidelity to give operators a true understanding of the downhole environment. Cerebro Force reduces the uncertainty and gives more accurate information on downhole torque, drag, and mechanical specific energy.

Halliburton’s Cerebro Force sensor is a first-of-its-kind technology that captures weight, torque, and bending measurements directly from the bit.

01:17

Provides operators with unmatched data capture capability on drilling forces experienced at the bit, delivering a clearer picture of the downhole drilling environment. Operators now have access to the most important drilling performance measurements, captured from within the drill bit which is the most critical location within the bottomhole assembly.

The sensor is integrated into the bit and does not impact bit-to-bend or bit-to-pad distances for directional performance.

Compact, integrated design is compatible with all BHA types, including motor and rotary steerable systems, and allows for use with any measurement-while-steering or logging-while-drilling system.