Search

Search

Search

Search

By collaborating at the inception of CCUS projects, Halliburton helps deliver effective CO2 storage

Contact UsHalliburton addresses the unique properties of every carbon capture, utilization, and storage (CCUS) project, including site selection, emissions processing, transportation, well design and construction, and long-term monitoring. We help mitigate risk through our subsurface knowledge, formation evaluation, integrated software solutions, and long-term monitoring technologies.

With over 100 years of experience in well construction, planning, and design, we’re uniquely positioned to provide CCUS project solutions. We actively engage with our customers throughout the entire CCUS lifecycle, from planning and permitting support to execution and monitoring, to help our customers achieve safe, compliant CO2 underground storage.

Halliburton's integrated and multidisciplinary studies, project planning, and leading technologies address uncertainty in CCUS projects, optimizing storage site selection and helping to manage risk. From initial site screening and determining site viability to modeling storage capacity and providing permitting support, Halliburton provides the foundation for a successful carbon sequestration project.

Today, hundreds of carbon capture, utilization and storage projects are in early development globally, however the number of commercial CCUS sites rem

02:05

Halliburton helps minimize risk by leveraging industry-leading technology to understand CO₂ properties, waste stream characteristics, fluid dynamics, and subsurface reactions to CO₂ injections, helping to predict the long-term condition and potential risks of storage sites. Before the project even begins, we can design an optimal injection system and plan for measurement, monitoring, and verification (MMV).

Halliburton leverages over 100 years of complex well construction experience to engineer reliable, high-integrity wells that meet or exceed regulatory requirements for CCUS projects. Whether it's helping to ensure long-term zonal isolation, assisting with the elimination of potential communication between sensitive zones, or aiding to protect the casing, we provide solutions to achieve dependable barriers from surface to underground storage.

Halliburton Global Director of Evaluation and Production Consulting Steven Knabe presented at the 2024 Carbon Capture & Hydrogen Technology Expo, to discuss how lessons learned from enhanced oil recovery (EOR) can help provide a path forward for CCUS and industrial decarbonization strategies.

Read blog

Halliburton's professionals design measurement, monitoring, and verification (MMV) plans that comply with regulatory standards to help reduce risk and detect CO₂ leakage. We link modeling to real-time monitoring and surveillance systems that integrate logging, fiber optics, and subsurface gauges. Our CCUS monitoring solutions help provide early detection of potential leakages and increase operational speed.

Provides enhanced resistance to CO₂, lower permeability, and increased elasticity in comparison to conventional Portland cement systems.

StrataXaminer™ provides more accurate well data to better evaluate production potential and increase return on investment.

Integrated suite of high-resolution modeling tools for CO2 storage exploration, monitoring and prediction. The software addresses key aspects of CO2 storage workflows: formation storage prospecting, capacity estimation, well injectivity, formation pressurization, plume trapping, and dissolved CO2 dispersal.

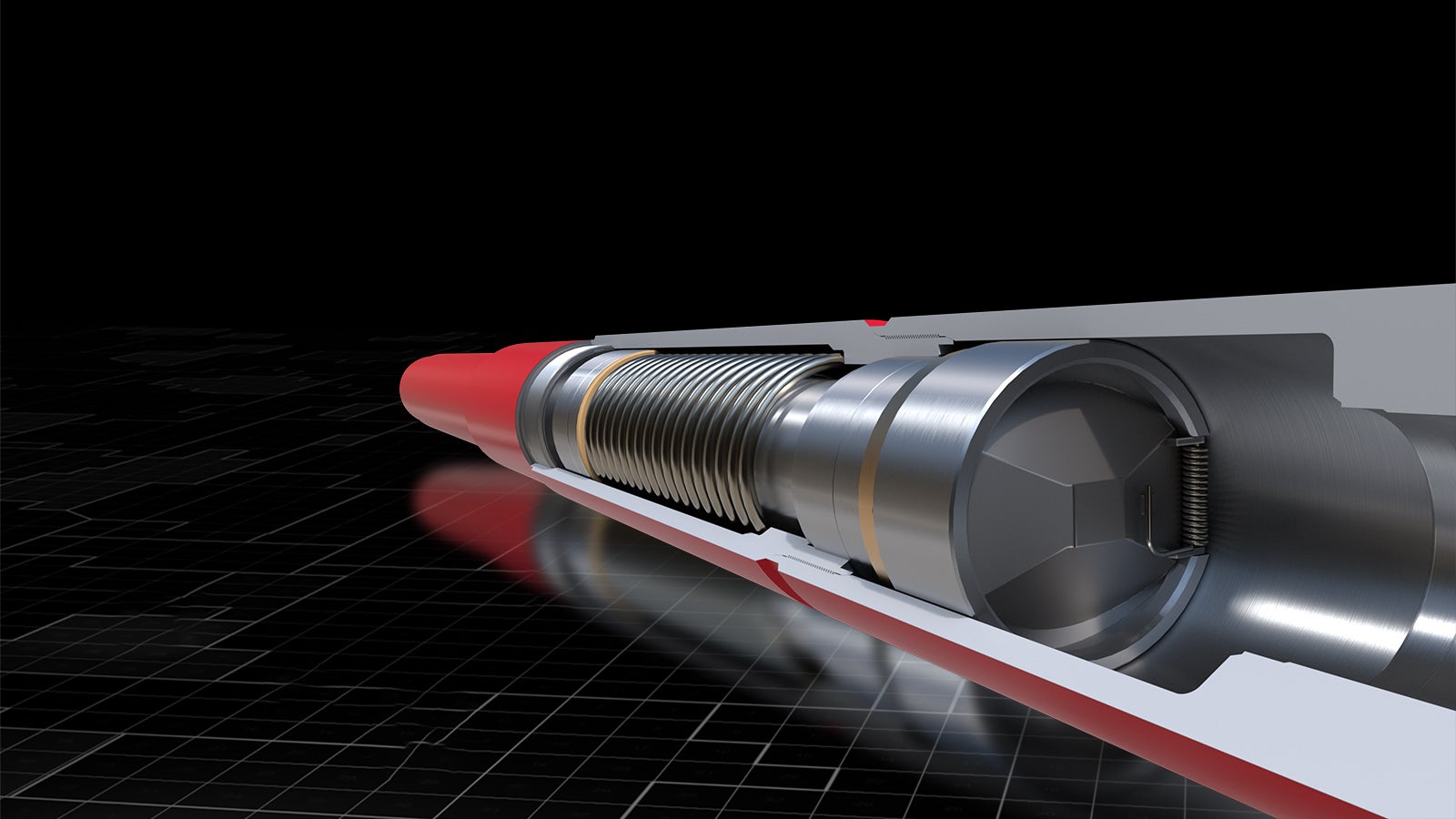

NeoStar CS TRSV retains the features of the legacy SP safety valve and is equipped with the ultralow temperature operation and survival capabilities for CCUS.

Deep-penetration, high-performance sealant ideal for carbon storage, chemical disposal wells, and permanent plug and abandonment.

Hercules™ horizontal pumping systems (HPS) are an alternative to positive displacement, split-case, and other surface pumping options.