Search

Search

Search

Search

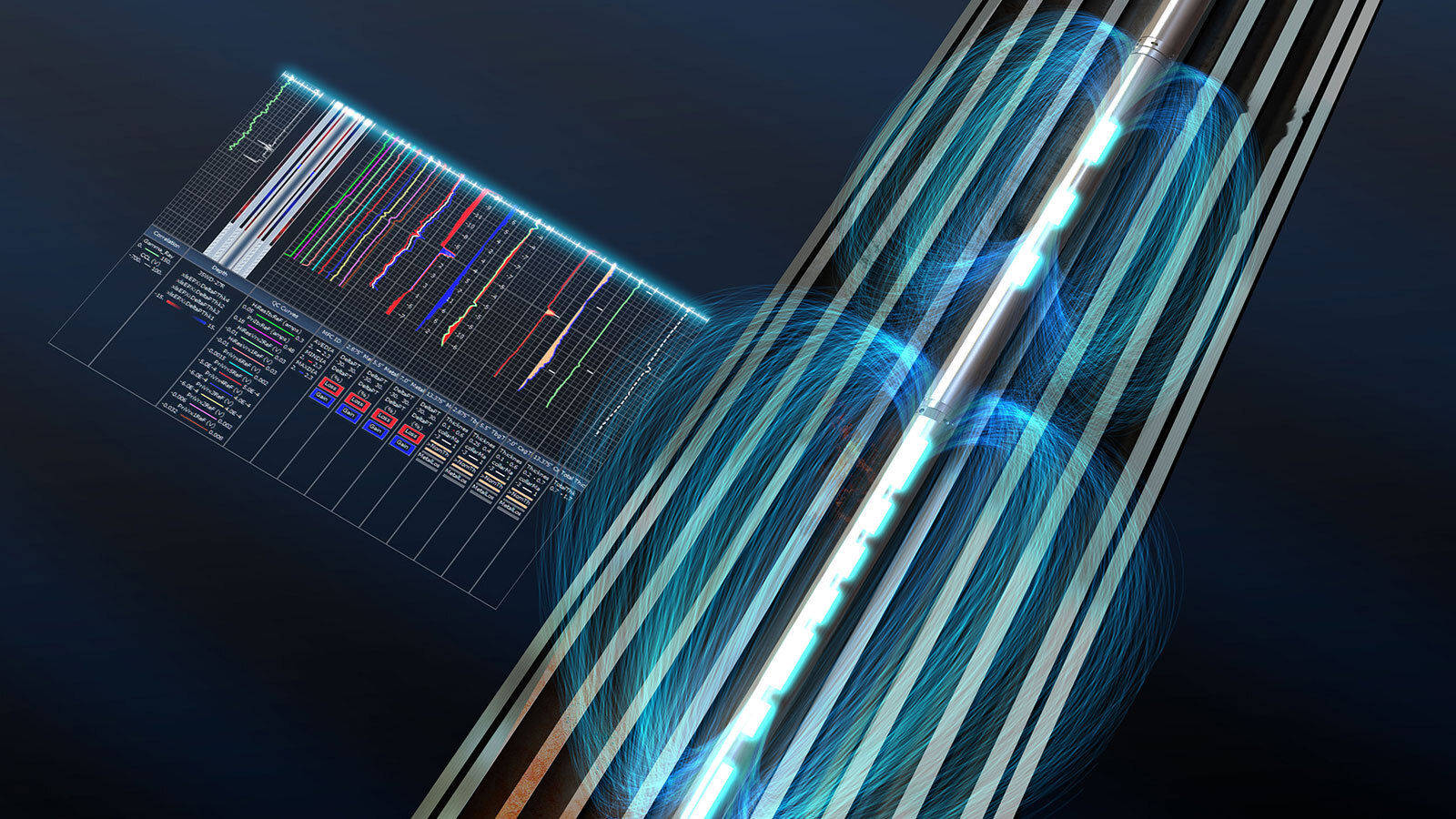

Using accurate High-Definition Frequency (HDF) technology, the Halliburton Electromagnetic Pipe Xaminer V (EPX™ V) determines the percentage of metal loss in one to five concentric pipes in a wellbore. This enables one-trip examination and quick assessment of pipe conditions. EPX V helps operators reduce diagnostic time, collect comprehensive data for monitoring programs, and determine the right solution for any nonconformity in completion.

The EPX V offers a true understanding of where corrosion or metal loss is coming from and measures corrosion rates from inside and outside the well.

02:27

Maximum temperature

PSI maximum pressure

Inches maximum tool outer diameter

ft/min maximum recommended logging speed

The Halliburton EPX V service induces HDF electromagnetic energy into the surrounding pipe that propagates through the concentric well strings with no wellbore fluid influences. The returning signals yield information on metal loss in the tubulars. HDF variance algorithms identify the magnitude and location of corrosion-induced defects for a quick total-thickness calculation determining the overall condition of the pipe structure. The HDF data, through post processing, also provides the metal loss in each pipe.

Operating off mono-conductor wireline or in memory mode on slickline, EPX V ensures more efficient wellsite operations, well construction solutions, rigless intervention, and conveyance flexibility. The EPX V service combines seamlessly with Halliburton diagnostic solutions such as the Acoustic Conformance Xaminer® (ACX™) service, production logging, pulsed-neutron logs, and bond logs.