Search

Search

Search

Search

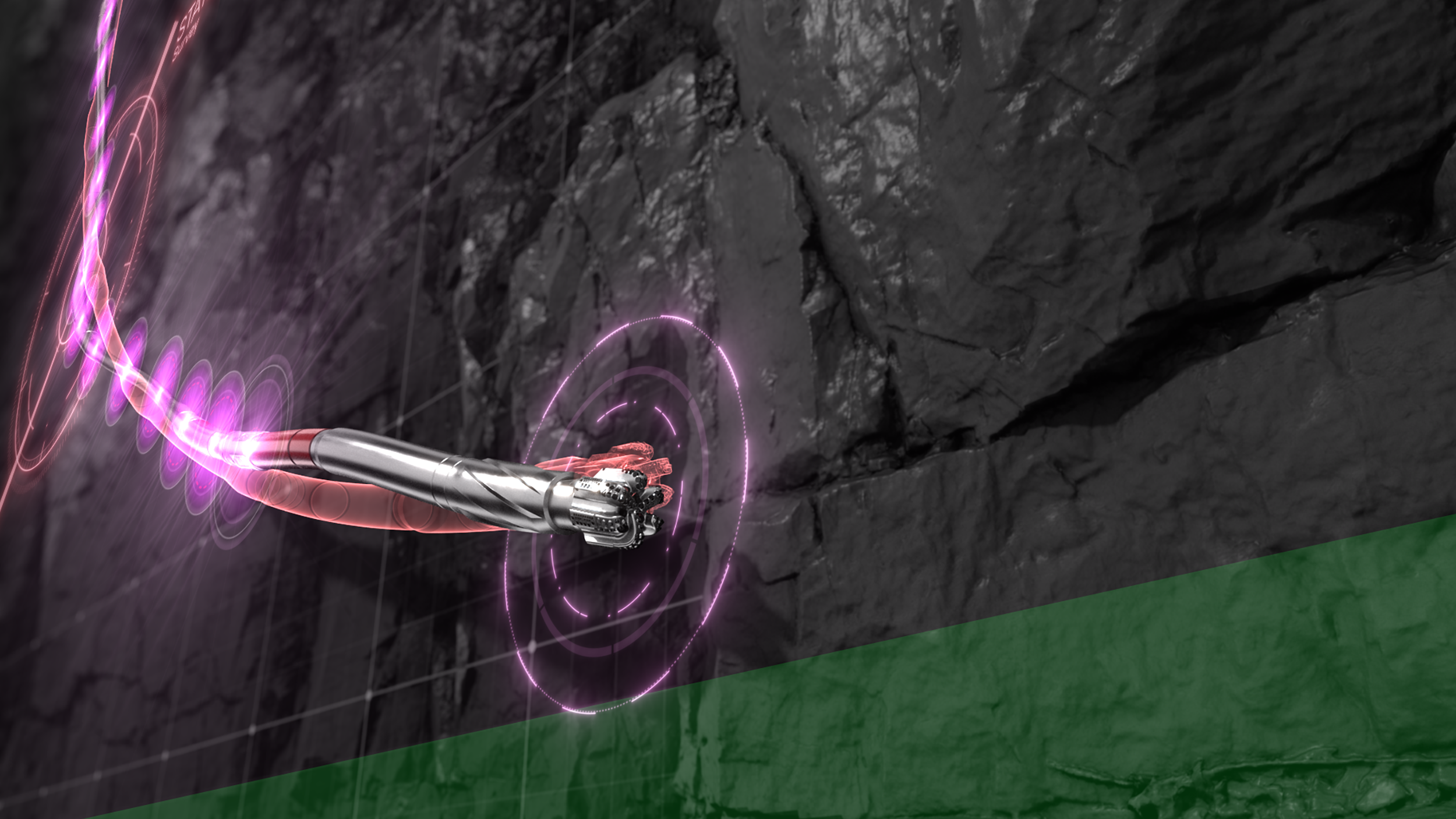

Precise measurements, true wellbore positioning

Talk to an expertThe GuideStar continuous definitive survey measurement from Halliburton uses high-resolution sampling for accurate wellbore placement. As part of the iStar® intelligent drilling and logging platform, it processes the measurements from the BaseStar® service and provides definitive-grade surveys to optimize wellbore placement, enhance well delivery, and improve wellbore quality.

GuideStar Service

The service enhances TVD placement accuracy with survey measurements taken at a high sampling rate while drilling. The density of the recorded samples allows for a wellbore correction up to every foot.

Precise wellbore placement through continuous, high-resolution survey measurements.

01:32

The constant, high-resolution data sampling increases understanding of the centerline wellbore placement through precise true vertical depth (TVD) positioning. This helps operators hit geologic targets, maximize reservoir contact, and reduce survey time through pumps-off survey acquisition. The service also enables proactive, real-time steering decisions to avoid reducing rate of penetration (ROP) when landing a well or at critical wellbore intervals.

The GuideStar service improves positional certainty to increase drilling efficiency. The high sampling rates enable more accurate micro-dogleg calculations, which help operators optimize real-time drilling decisions and minimize tortuosity throughout the wellbore. This results in better borehole quality and smoother casing runs.

GuideStar service

Wellbore surveying provides definitive data that depict the position of the borehole in three-dimensional space.

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere.

Integrates critical measurements for wellbore placement, drilling performance optimization, and borehole quality.

Offers a digital transformation of drilling solutions to reduce operational risks and ensure consistent well delivery.

Automation-enabled platform designed specifically for longer well applications in harsh environments.