Search

Search

Search

Search

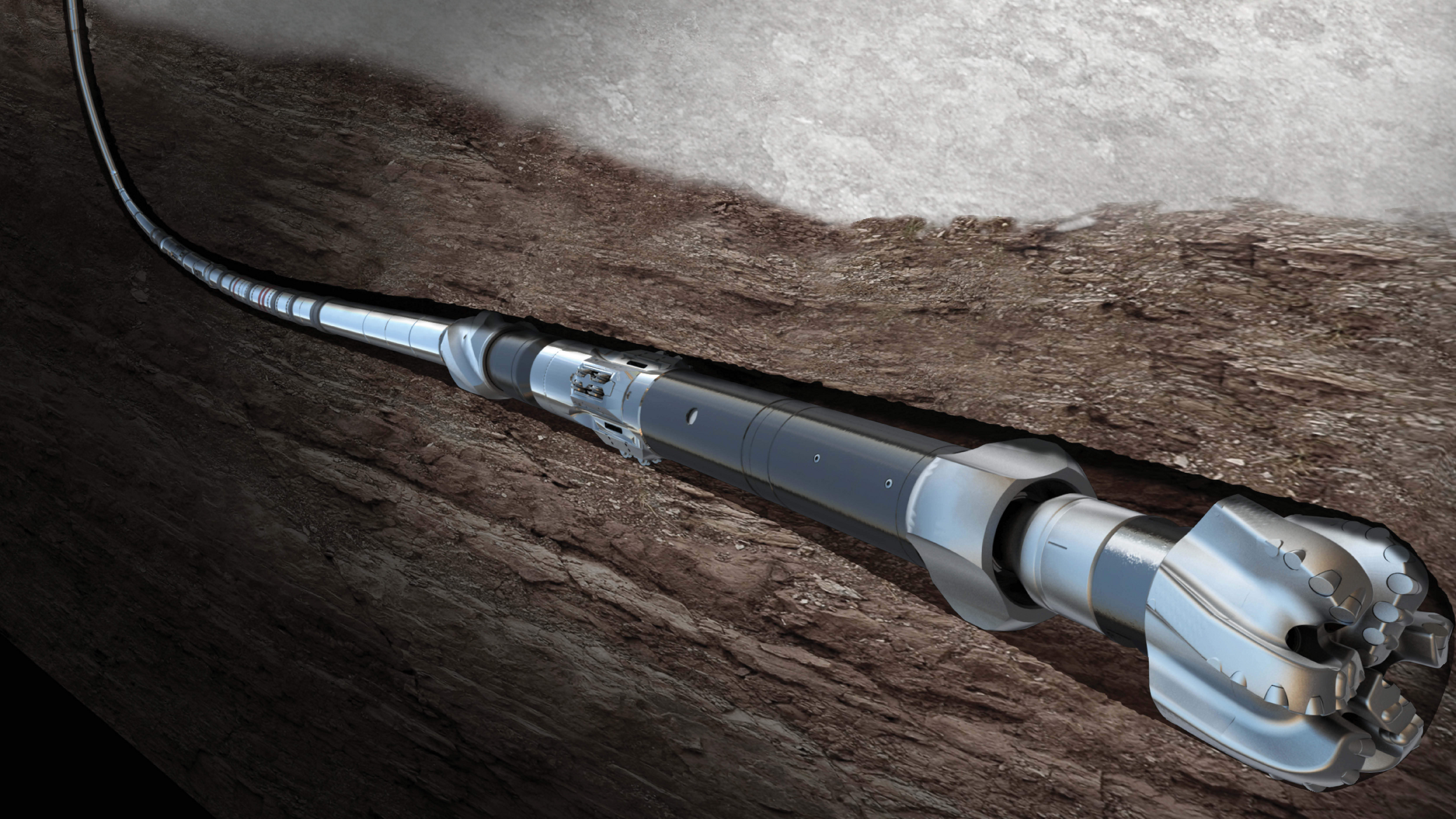

Operator drills longest-ever well in sub-zero temperatures using superior fragile gel fluid

Download PDFUnconventionals

Use a drilling fluids solution to drill a well to a record-breaking total depth

Extending the production life is critical to any operator’s field development program. This is achieved by using a variety of sustainable Halliburton Baroid technologies and approaches to unlock the ability to reach new reserves, by drilling longer, more complex, extended reach, exploration wells.

The ability to drill longer wells can help increase the longevity of the field development program. Successfully proving that BaraECD can deliver the high-performance fluid required (in a prior Artic region well) was key to the operator attempting this record-breaking well. The previous campaign showed that 10,230 m could be reached while maintaining an equivalent circulating density (ECD) below a fracture gradient of 17.2 ppg, without loss of performance, or increase in risk. This well pushed that accomplishment to 14,600 m (47,900 ft), while maintaining an ECD below the fracture gradient of 17.5 ppg, at a flow rate > 500 gpm.

Having successfully proven BaraECD drilling fluid on the previous well, albeit to a lesser depth and with less stringent requirements, the same base formulation, mixing procedures, and methodical approach to treating the fluid while drilling ahead were applied.

BaraECD components were mixed at the liquid mud plant (LMP) in sub-zero temperatures through a BaraShear™ high throughput shear pump at 2,700 psi and 5.4 bpm, and delivered to the rig with the same properties as the previous well (within 5% of laboratory specifications).

Despite running 325 mesh screens on all shakers, previous experience suggested the NAF would gain low gravity solids towards the end of the section, jeopardizing the gels and PV that allow the fluid to deliver such staggering ECD performance. In order to prevent excessive rises in these properties, weighted and unweighted low rheology versions of the base formulation (with an optimized concentration of 6 ppb BDF-919) were prepared and utilized while drilling ahead. Due to limited mixing capacity when preparing for the completion phase, early preparation of premixed solutions was imperative. This ensured that the BDF-919 passed through the BaraShear pump and was fully dispersed.

To evaluate risk of weight fluctuations, all fluids were subject to ongoing daily VSST analysis (baseline comparison) and, at various stages, longer term static aging was performed to support the VSST data (LMP batch mixes, first footage drilled, at TD). All static age results showed excellent weight stability.

Drilling fluids graphics software (DFG™) was continually run, modeling current fluid specifications against actual geometric data, and comparing it directly to actual downhole pressure data from PWD (pressure-while drilling) sensors.

cP PV maintained

feet total depth (TD)

bbl of fluid mixed

The BaraShear pump and BDF-919 formulation successfully:

The BaraECD NAF system surpassed the previous drilling performance, delivering:

The DFG software delivered:

BaraECD® is a high-performing, stable, and versatile fluid system that challenging wells demand.

Halliburton completion fluids optimally prepare, repair, clean out, and complete the wellbore to maximize production.

Halliburton Baroid is at the forefront of the drilling and completion fluids industry.