Search

Search

Search

Search

Halliburton collaborates with Neptune Energy to free stuck drillpipe in subsea wellhead/BOP

Download PDFDeep Water

Provide technology for accurately cutting drillpipe inside the wellhead and BOP

North Sea, Norway

In the North Sea, the offshore Deepsea Yantai rig was drilling the Gjøa well for Neptune Energy, and, after the drilling operation entered the reservoir section, the drillstring became stuck in the wellbore. While working with another service provider, the operator was attempting to free the stuck string when the drillstring separated into two sections. These parts of the string blocked the blowout preventer (BOP) so that the BOP was unable to close and prevent a potential well stream leak without cutting the two pipes with the shear ram. After a week with no resolution to this situation, it was vital to solve it to avoid any potential well control issues. It was also necessary to cut the pipe to the latch on Fish #1 inside the riser. An attempt to cut the pipe with a plasma cutter had failed due to the risks of damaging the wellhead and BOP area. The main service provider on the rig was unable to solve the situation; consequently, the operator needed to find a service company with ready resources and a solution. Quickly responding to the operator’s request for assistance, Halliburton recommended its ClearCut™ powered mechanical cutters, and then collaborated with the Neptune Energy drilling team to ensure that all the necessary equipment and personnel were available and ready to go for this complex operation.

The risk of damaging the riser and the BOP while performing the cut was high, which eliminated the possibility of using the explosive or plasma cutters that were on the rig. The well was stable, but the potential of having a well control issue was increasing with time, so Halliburton was tasked with resolving this situation that the previous services provider could not solve.

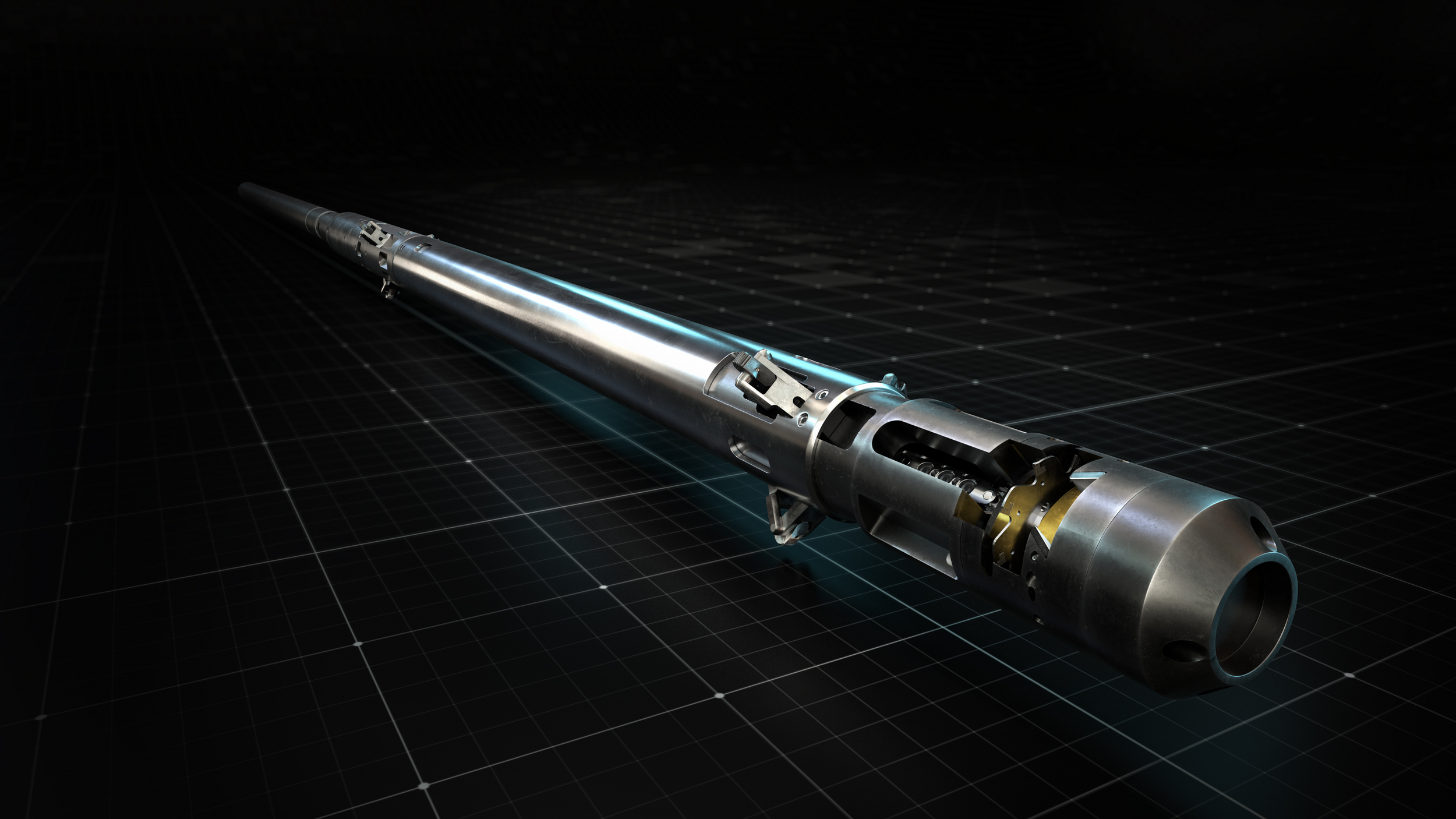

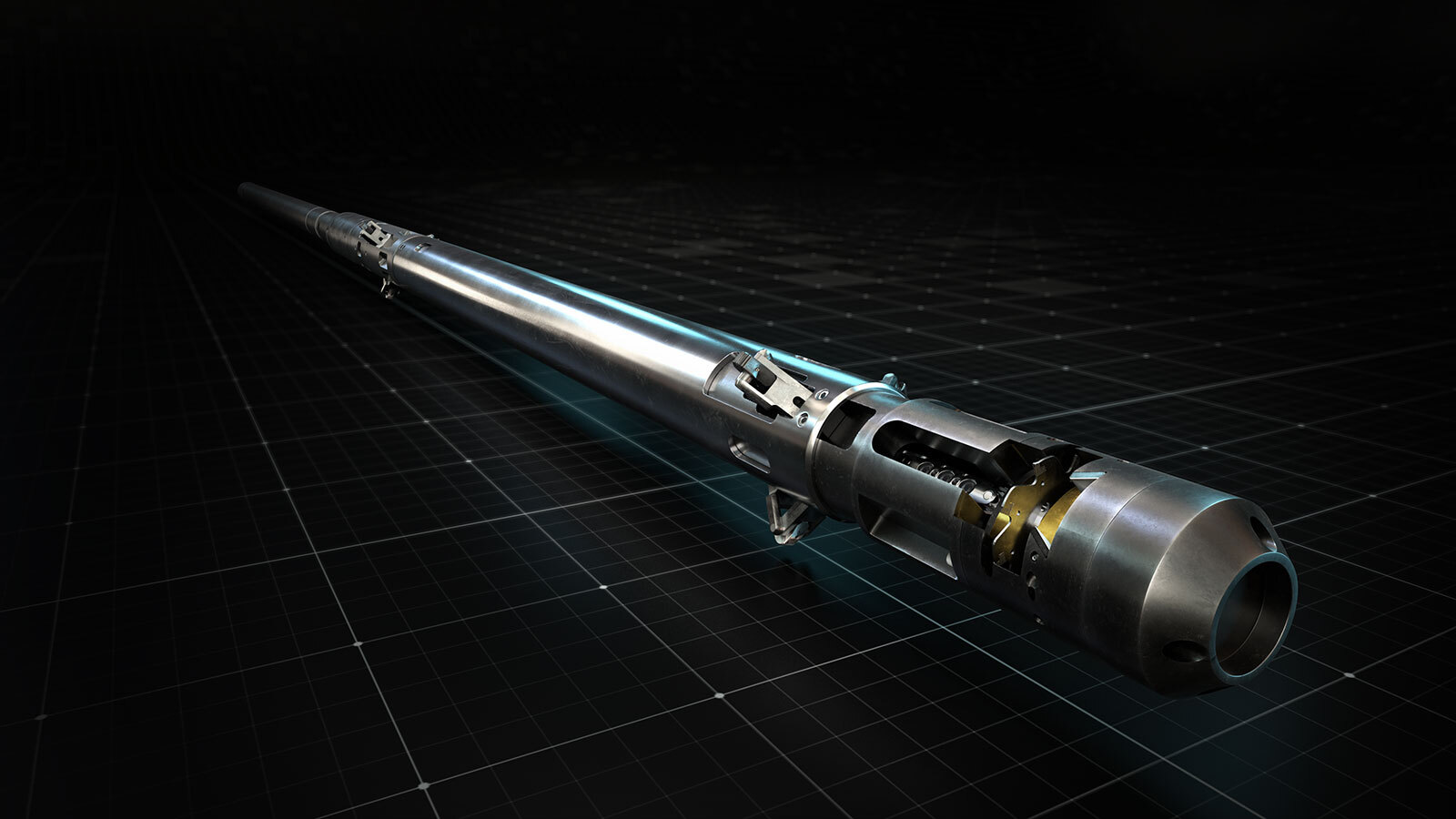

Halliburton was able to quickly respond with a solution to Neptune Energy’s issue by recommending its ClearCut powered mechancial cutters. This innovative technology is:

Safe: ClearCut technology eliminates radio silence, explosives, and chemicals. This unique cutting system has a far lower risk for health, safety, or environmental (HSE) incidents than traditional cutting methods.

Accurate: The ClearCut cutting tool’s accuracy ensures that only the pipe is cut, with no damage to the outer casing wellhead, BOP, or riser. This critical function is beyond the capability of most traditional methods.

Efficient: This highly efficient cutting mechanism typically cuts 5.50-inch tubing in less than two minutes, with successful wireline intervention in a single run. Real-time data gives immediate notification of cutting success, thus eliminating operational uncertainty. Additionally, minimal surface equipment is required. Typically, just a compact power supply unit and a laptop are required to run the control software and to interface with the wireline unit’s depth system. For the highest cutting efficiency, the system can be deployed on any wireline unit.

Effective: ClearCut powered mechanical cutters perform precisely located, machine-shop-quality radial pipe cuts, regardless of depth and pipe compression – thus giving the important advantages of having a completely clean pipe end. The tool’s high accuracy ensures that only the pipe is cut, with no damage to the outer casing or control lines.

Successful cuts were performed on the first attempt

Damage to the riser, casing, or BOP

Within 37 hours of being contacted by Neptune Energy, the Halliburton team performed the first cut of the operation – effectively stopping five days of non-productive time (NPT) on the rig and enabling the operator to commence with its fishing operation. In all, four successful cuts were performed on the first attempt without any damage to the riser, the casing, or the BOP. After retrieving the strings to surface, the Neptune team observed the machine-shop-quality cuts made by the ClearCut tool. Consequently, the customer recognized the value of the ClearCut cutters and requested that the Halliburton crew stay on the rig to provide this service until the end of the fishing operation.

ClearCut powered mechanical cutting tools perform precise, machine-shop quality, radial pipe cuts, regardless of depth and pipe compression.