Search

Search

Search

Search

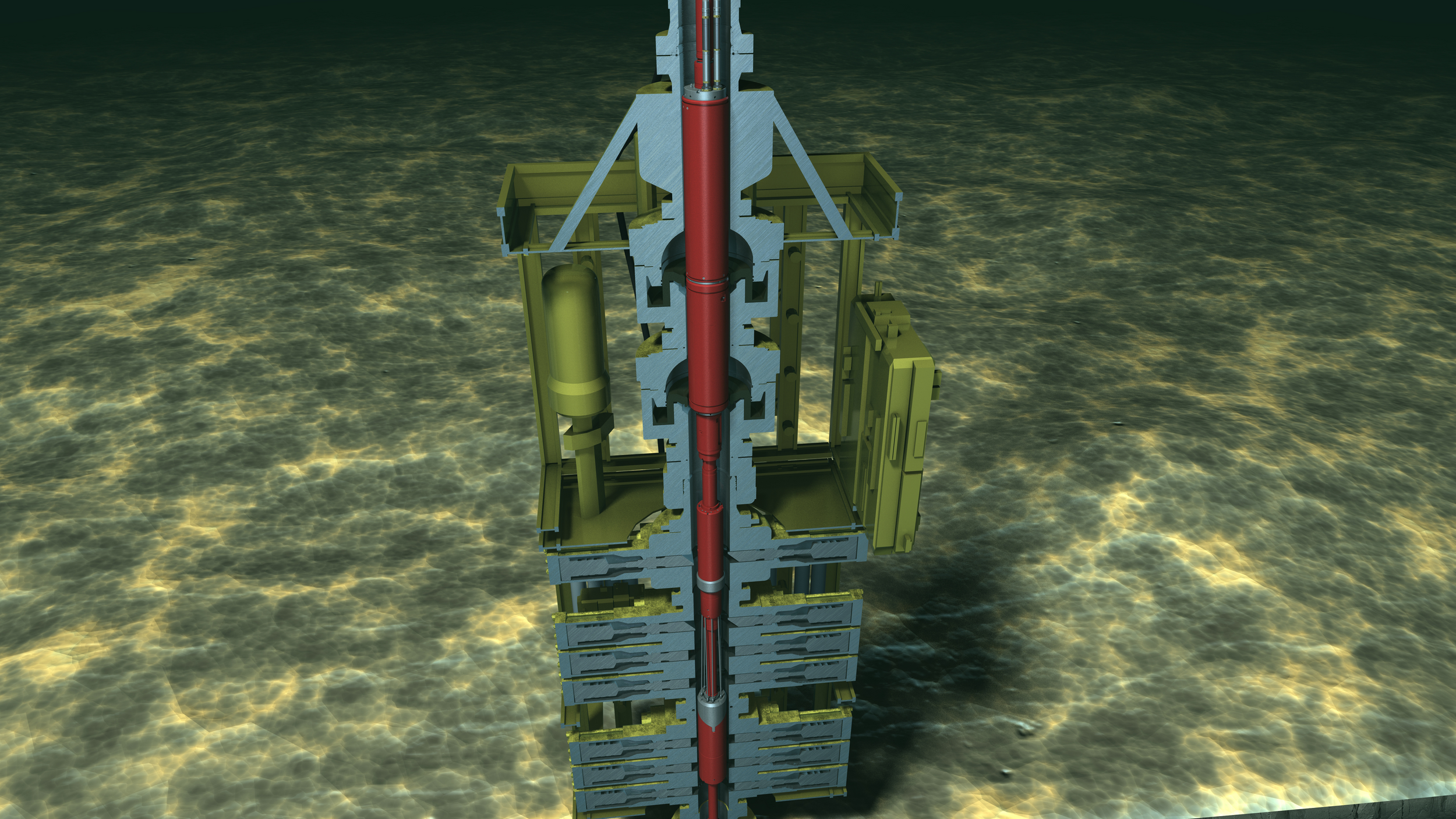

Electrohydraulic system offers rapid deployment, simplified operations, and reduced risks

Download PDFDeep Water

Streamline a safe well abandonment solution for two deepwater wells

Gulf of Mexico

An operator in the Gulf of Mexico needed a well abandonment solution for two deepwater wells and required that the intervention be as quick, safe, and cost-effective as possible. Halliburton deployed its electrohydraulic (EH) Dash large bore subsea safety system because it was easier and faster than traditional systems. The mobilization was successfully completed in only 30 days—two to three times faster than with traditional landing string systems—successfully delivering a P&A solution with zero nonproductive time (NPT) or safety issues.

Efficiency and cost effectiveness are critical in deepwater completions and interventions because of the risks of high pressures, rig mechanical failures, extreme weather conditions, and other unexpected emergencies. Traditional electrohydraulic subsea safety systems are large and complex, with multiple valves, complicated electronics, and multiple tubing connections, making these systems slow to manufacture and assemble, difficult to handle offshore, and inefficient to maintain and repair. With interventions taking days to weeks to complete, and with average deepwater rig rates in the Gulf of Mexico costing around $1.2 million a day, every hour wasted translates to tens of thousands of dollars.

For the P&A operation on its two active wells in the Gulf of Mexico, the operator needed to mobilize the rig, along with coiled tubing (CT) and equipment, within one month. Halliburton was approached for an efficient, cost-effective solution that would:

Halliburton used the Dash large bore subsea safety system as the primary safety barrier. Engineered to be simple to assemble, test, and run in hole, the electrohydraulically controlled system can be isolated from the lower landing string in less than 6 seconds and disconnected from the string in less than 10 seconds. With a customizable data-monitoring solution for the subsea safety functions, pass-through controls, and surface control system, the Dash system enables operators to calculate optimal performance, avoid NPT, and streamline deepwater operations.

Halliburton Gulf of Mexico subsea operations and Testing and Subsea technology teams collaborated with the operator to customize the system in order to interface with the blowout preventer (BOP) and THRT and to provide dual barrier isolation, unlatch capability, and a way to cut the CT string. Halliburton initiated the Design of Service (DOS) process, which was led by a Halliburton subsea engineer working closely with the operator’s subsea team. The DOS process defined pre-job testing, BOP stack layouts, job procedures, and a project-specific risk assessment. Halliburton assured the operator that the system would meet company standards without adding risk.

Nonproductive time (NPT) or safety issues

Hours to rig up the landing string

Days operating time

The Halliburton team delivered a fully customized Dash system landing string in less than 30 days, after having conducted a full EH system integration test in just four days. A comparable hydraulic subsea safety system would have taken more than three months. The landing string was rigged up offshore over the well center in only four hours, up to three times faster than with traditional systems. The real-time monitoring of the flow and pressure measurements by smart, redundant electronic controls provided immediate feedback of the downhole operations, enabling the operator to be more confident about critical well control during P&A operations. No NPT or safety issues were reported. In total, the Dash system provided more than 30 days of safe, reliable operation for the deepwater P&A procedure.