Search

Search

Search

Search

Average millout time proves to be less than four minutes, and small amount of debris allows millout of all plugs in each well without short trips

Download PDFUnconventionals

Reduce time and costs by efficiently removing over 60 composite plugs from well

Vaca Muerta Formation, Argentina

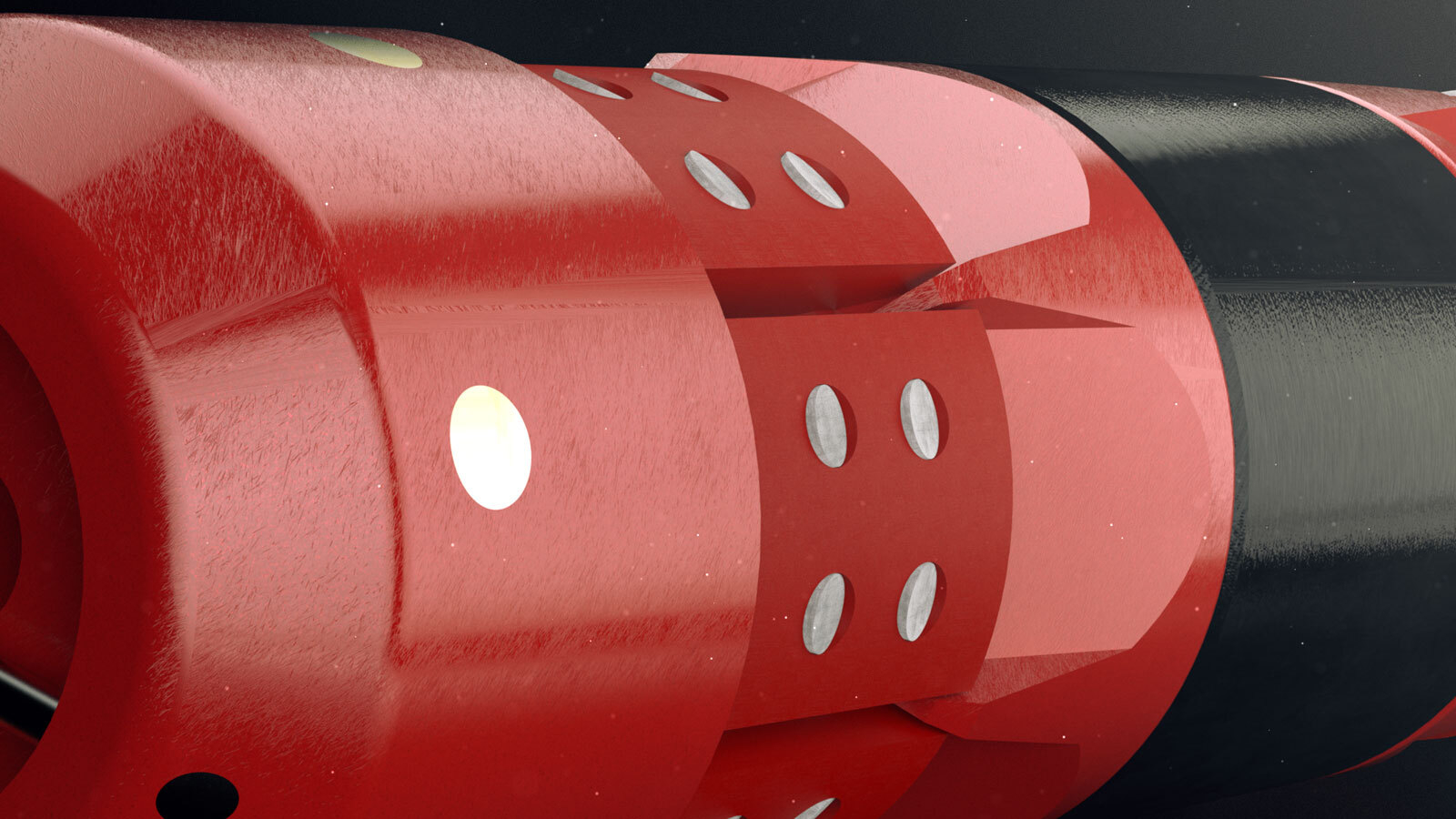

A major operator in Argentina’s Vaca Muerta formation was looking for a slim frac plug that could be pumped down in multiple wells with a horizontal section, and that would reduce service intensity and time associated with plug removal and cleaning wellbore. Halliburton proposed its Fas Drill Ultra frac plug, composed of easy-to-mill composite material. This new design has been enhanced for millability without sacrificing fluid efficiency.

After installing 4.5-inch Fas Drill Ultra plugs, the operator was able to safely remove more than 60 plugs from several wellbores, with an average millout time of less than four minutes per plug – a performance never seen before in the country. The job was performed without short trips, and returns seen at surface were smaller than with other plugs. This saved the operator several hours of operation, along with tens of thousands of dollars in the overall cost of the completion.

In an effort to improve efficiency and reduce costs, the operator sought to scale down the time and risk required to remove composite plugs from the wellbore by using a 2-inch coiled-tubing unit. At the same time, the required plug had to keep a reduced diameter to avoid sticking, due to the high occurrence of casing deformation in the area.

Halliburton recommended 3.50-inch Fas Drill Ultra frac plugs. The single-component designs for the slips and element package make a robust tool that is able to be pumped in extended horizontal sections.

By virtue of its shorter design and the most advanced composite and rubber materials, this plug helps reduce millout time, leaving less debris to recover from the wellbore. With no metal content, it also helps to save drill bit life and avoid damage to the casing.

to remove all plugs in second well

minutes per plug average millout time

plugs successfully removed

issues to pump and set plugs

Sixty-six Fas Drill Ultra frac plugs were pumped and set at the desired depths without issues. The operator was able to safely remove all plugs from the first well in less than 41 hours, including running in hole (RIH) and pulling out of hole (POOH) operations, with an average milling time of 4.2 minutes per plug. For the second well, all plugs were removed in 35 hours, with an average milling time of 3.6 minutes per plug. The milling time in the first well only represented 2.3 percent of the total time, including the rig-up operation – while, for the second well, the milling time was 3.3 percent of the total time. Both values were negligible compared to the entire job time.

The small amount of debris from the Fas Drill Ultra frac plugs helped the operator to retrieve the plugs more easily at the surface, thus reducing risk and also saving significant time and cost by allowing the operator to perform the job without any short trips.

Greatly reducing the duration of the coiled-tubing millout saved the operator tens of thousands of dollars in cost, along with days of operation. The operator is continuing to focus on efficiency and on partnering with Halliburton for the best completion solutions.

Fas Dril Ultra frac plug

This high-performance frac plug is rated up to 10,000 psi for zonal isolation during wellbore stimulation and combines the Halliburton industry-leading frac plug design with the most advanced composite and rubber materials.

Download Data Sheet

Halliburton frac plugs isolate zones during stimulation, bringing production online faster.