Search

Search

Search

Search

Advanced automation solutions deliver best-in-class section

Download PDFUnconventionals

Delivering the landing section with 100% automation

Kuwait

Drilling automation solution package includes:

The Bahra Field was the first structure discovered in Kuwait with the first well being drilled in 1916. Located near Kuwait Bay, this is a key field for Kuwait Oil Company (KOC) to achieve aggressive production goals, as it is one of the highest potential fields with over 200 wells drilled to date. Most of those wells are unconventional and require horizontal drilling to target a tight carbonate reservoir.

Bahra Field’s distinctively complex geology makes the implementation of remote drilling risky, even for the most experienced directional drillers. A recent benchmarking exercise showed the rig used to drill the existing wells is the slowest-performing rig in the area. Pump efficiency has been historically low, and only by following and measuring hydraulics parameters in real time could efficient hole cleaning be done. The interbedded formations in the 8-1/2 in. section of interest had different formation indexes, potentially causing vibration and varying bottomhole assembly (BHA) behavior. Another challenge was to avoid abrupt changes in dogleg severity (DLS) response to ensure a smooth hole profile, essential for a smooth liner run. To combat these challenges and uncertainties, the Drilling Engineering Solutions team proposed a comprehensive, automation-driven package in line with KOC’s 2040 vision to drill faster while maintaining consistency without compromising safety.

automation throughout the section

faster ROP than best offset

casing run time in the field

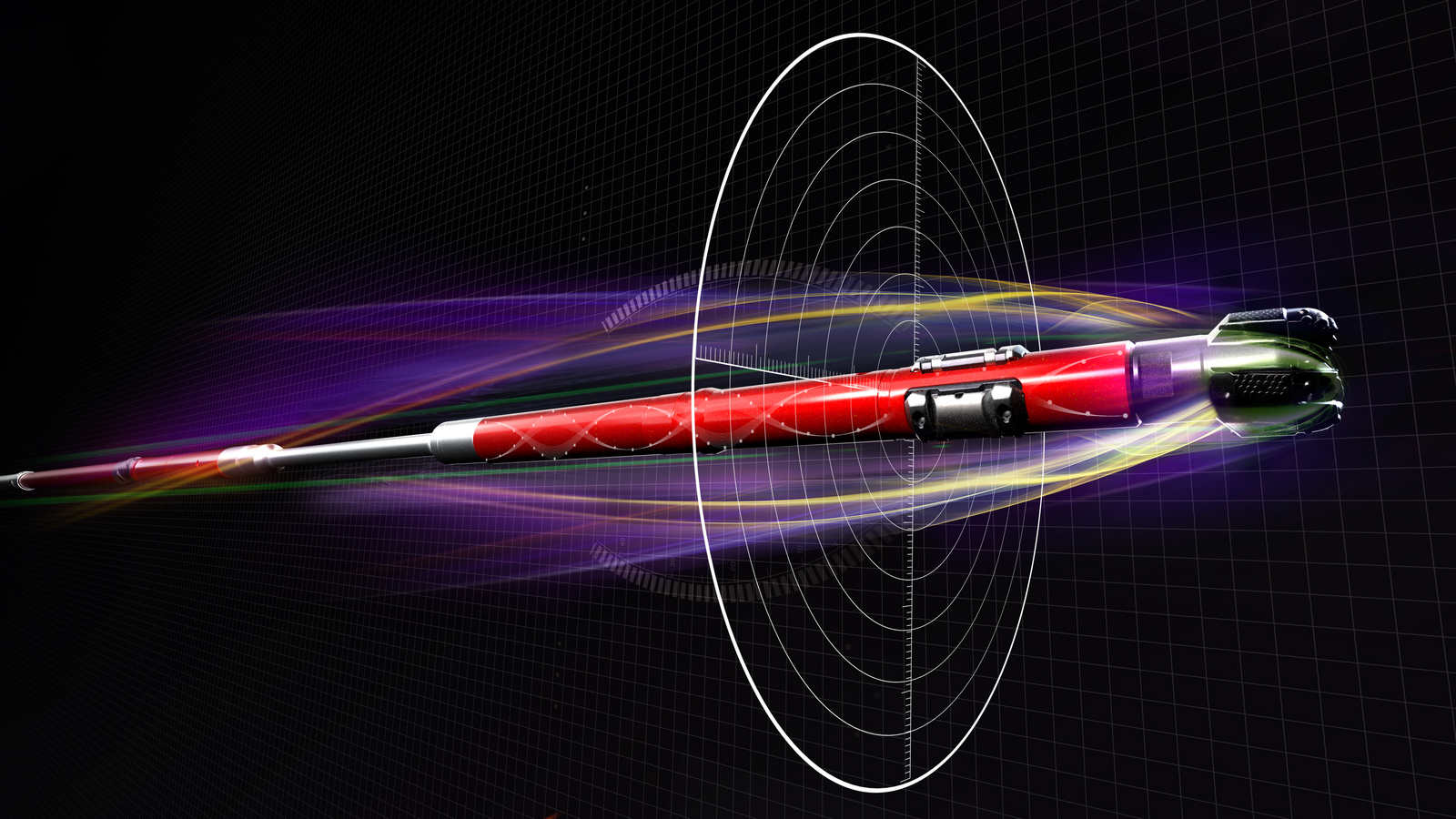

The proposed drilling automation solution was comprised the latest drilling technology tools. The LOGIX® drilling performance was run to drive the automation-enabled iCruise® intelligent rotary steerable system (RSS), and the smart PulseStar® high-speed telemetry system provided downhole measurements delivered to surface in real time for effective decision making.

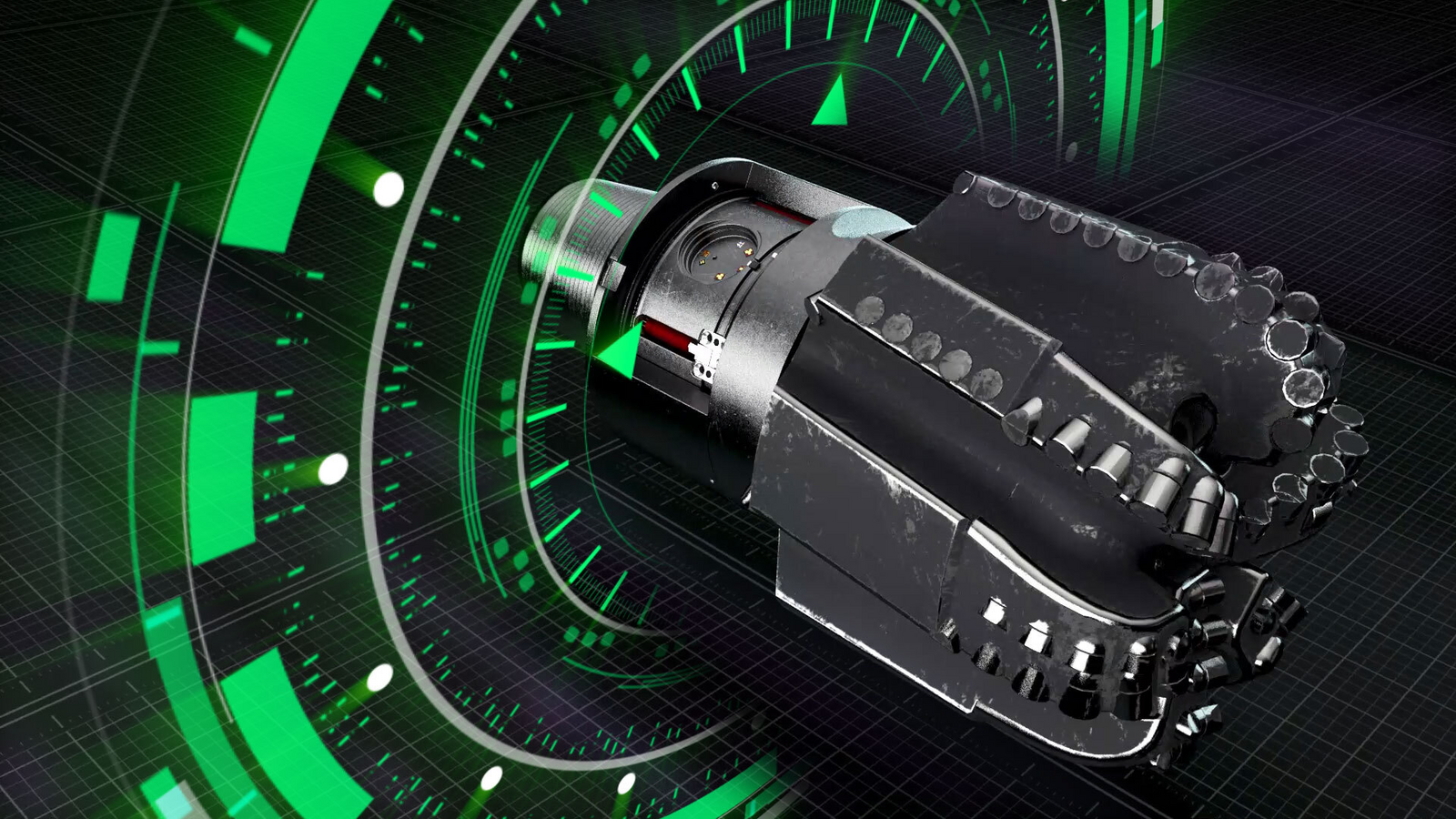

Several automation functions were executed—directional steering, trajectory control, vibration, and hydraulic management—with various control levels and limitations posed by the drilling rig. The PulseStar service accommodated the increased amount of data needed for LOGIX to close the communication loop of the automation bundle. A unique GeoTech® GTi drill bit was designed for the application and run with CEREBRO® in-bit sensing. The in-bit sensors provide direct measurements of weight-on-bit (WOB), torque-on-bit (TOB), bending-on-bit (BOB) vibration, and rotational speed as close to the bit-rock interface as possible. Utilizing these measurements, along with Design at the Customer Interface (DaTCI™) bit customization, helped reduce or eliminate inefficiencies caused by the previous bit, BHA design, and parameter selections. Improved drilling efficiency increased the rate of penetration (ROP) and run length, ultimately lowering overall well construction costs. The WOB, TOB, and BOB measured at the rock interface mitigated surface measurement uncertainty, provided a better understanding of the downhole environment, and enabled more accurate calibrations of drilling torque and drag models. The in-bit parameter sensing device integrated with the high-speed telemetry system provided a complete closed-loop workflow.

The integrated, highly engineered solution helped KOC move toward its 2040 vision to achieve target production with reduced human intervention and optimized efficiency and performance, while reducing HSE risks. This automated solution delivered a record-breaking 30% faster ROP than the best offset well in the field, seamlessly achieving a required 7deg/100-ft DLS. LOGIX controlled and drilled the planned section 100% without the need for drilling engineer involvement. The result was a significant improvement in overall performance, providing a smooth hole and landing the well perfectly in the reservoir target. Notably, this goal was accomplished despite one of the historically slowest rigs in North Kuwait. The drilling dynamics and vibrations were recorded to assist in future well modeling to achieve higher accuracy and further improve the performance roadmap.

The autonomous drilling platform orchestrates the rhythm in which the RSS executes commands to stay on the planned well path, enabling a virtually seamless workflow. LOGIX, in combination with other carefully selected tools and remotely controlled, delivered multiple record-breaking results for the field, in addition to lower overall well construction costs for the customer. This project raised the bar by showcasing the first-ever autonomous directional drilling run in Kuwait.

Drill to Produce Automation Journey

An integrated autonomous drilling solution that helps reduce operational risk and uncertainty to deliver wells reliably, repeatably, and consistently.

View Data Sheet

Fully digital and web-enabled to monitor and control drilling and logging operations from anywhere.

Reduce well time through fast drilling, fast tripping time and quicker casing drill outs.

The Halliburton Cerebro Force™ in-bit sensor improves drill bit performance, giving operators data needed to optimize use for the length of a run.