Search

Search

Search

Search

First XtremeGrip® ELH installation provides V0-qualified gas-tight seal in harsh, sour-gas environment

Download PDFExpected high pressure and harsh environment

United Arab Emirates

Operator’s first exploratory gas well in the area.

Flawless execution of first XtremeGrip expandable liner hanger installation exceeded operator expectations.

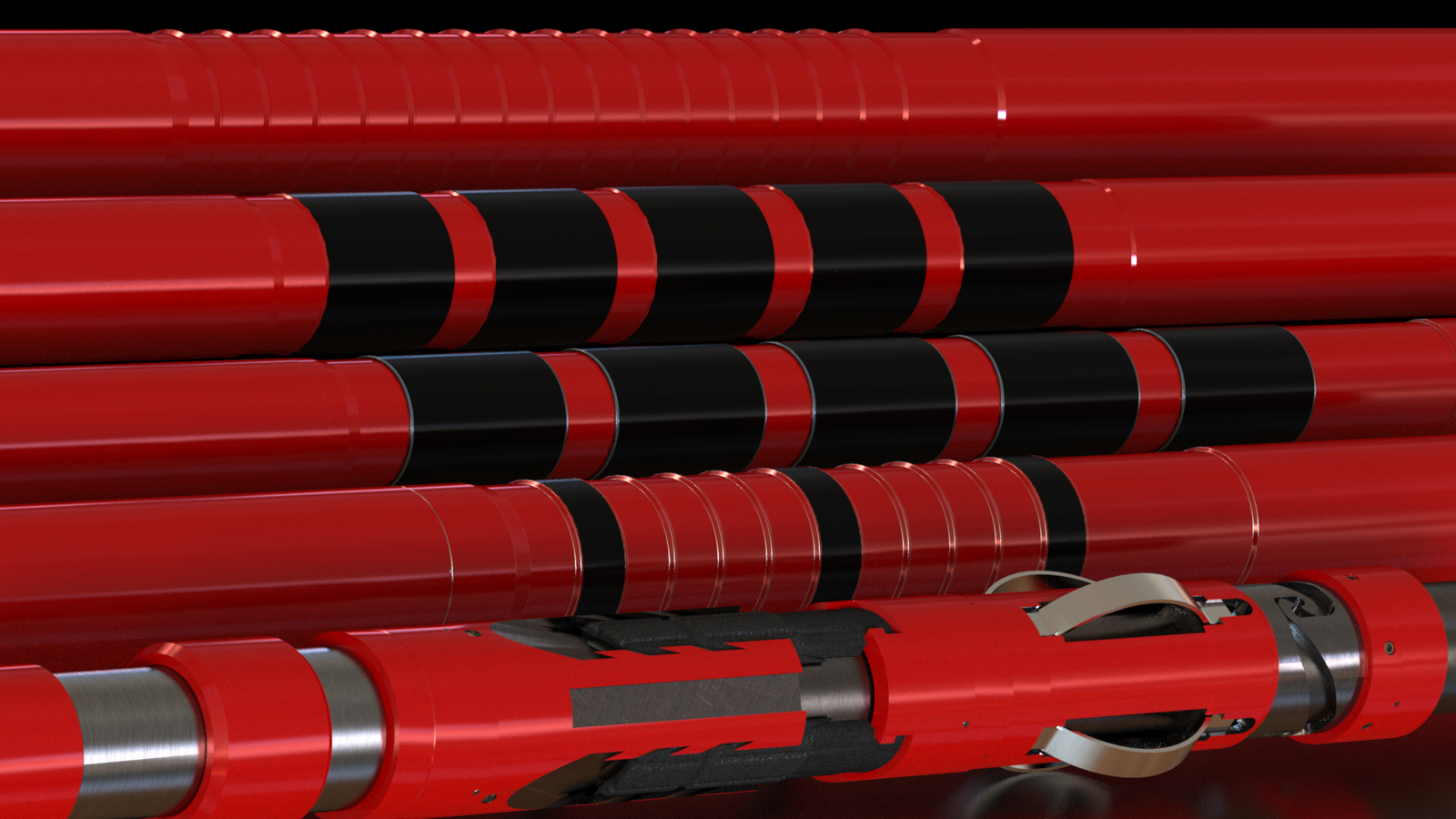

An exploratory gas well planned as part of a high-profile project offshore required a liner hanger solution to overcome a challenging well design and very tight casing clearance. Successful liner deployment to the required setting depths and reliable liner-top sealing were crucial to ensure well integrity and ultimately reach the overall well target depth (TD). Halliburton recommended an 11 3/4 x 13 5/8-inch XtremeGrip® expandable liner hanger system for a tight section, with high losses expected during run in hole and cementing. This marked the first XtremeGrip liner hanger installation for the operator in this region.

This critical project was the first performed by the operator in the country’s offshore sector. The offshore exploratory well targeted reservoirs in high-pressure/high-temperature (HP/HT) sour-gas formations. The liner hanger system design had to account for the harsh environment and fluid loss concerns during liner deployment to help ensure operation success.

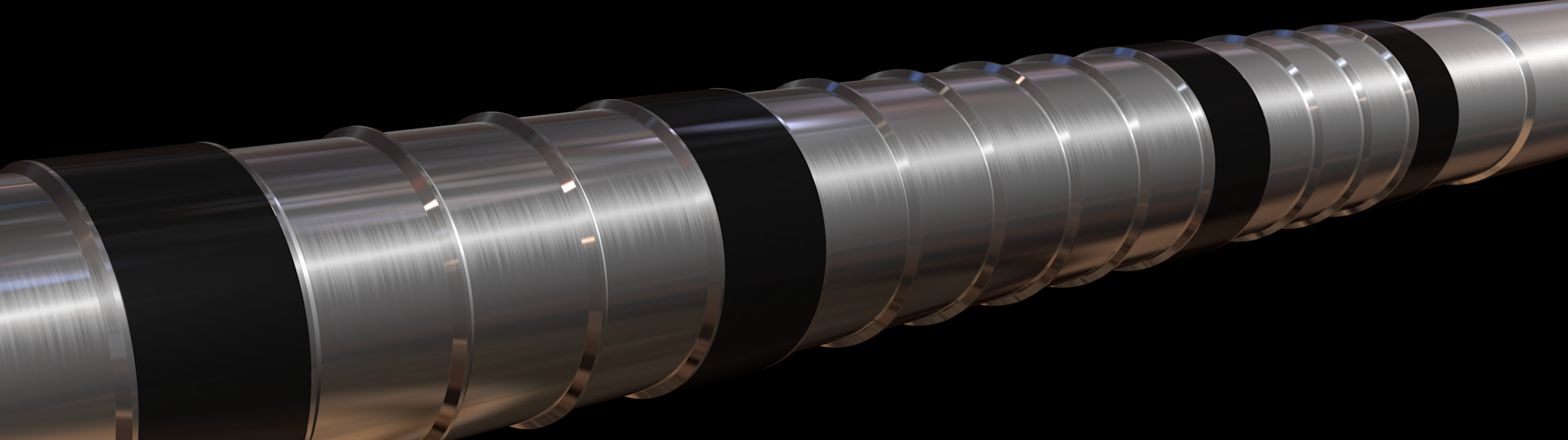

Halliburton proposed an 11 3/4 × 13 5/8-inch XtremeGrip liner hanger system, which provides field-proven, reliable performance in elevated pressures and temperatures. Its clean-form, simple design with a smooth radial flow path allows for an unrestricted bypass area, reducing equivalent circulating densities (ECDs) and potential fluid losses.

flawless execution of XtremeGrip® ELH installation

asset value

operator’s confidence in the technology

A multidiscipline Halliburton team, comprising personnel from the Liner Hanger, Baroid and Cementing product service lines (PSLs) collaborated with the operator throughout the planning and execution phases to help ensure the job design met the critical well objectives. During deployment, the XtremeGrip® liner hanger system worked through tight spots, successfully reaching the planned TD. Utilizing the SSR-II™ dual plug system and the Commander™ 1000 cement head with wireless remote control, the Cementing team cemented and set the liner as planned, providing an ISO 14310 V0-qualified, gas-tight seal so drilling could continue. This successful XtremeGrip expandable liner hanger installation proved its ability to maximize asset value and increased the operator’s confidence in the technology as a viable solution in future applications.

Data Sheet

High-performance metal-to-metal sealing technology ideal for complex deepwater wells and ultra-high temperatures for geothermal applications.

Product Information

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.

Designed for offshore operations to surface launch balls or darts in order to operate subsea plug sets and associated tools.