Search

Search

Search

Search

Gas-tight, liner-top isolation solution solves operator’s gas migration challenges

Download PDFUnconventionals

Overcome gas migration challenges through installation of an isolation system

Uzbekistan

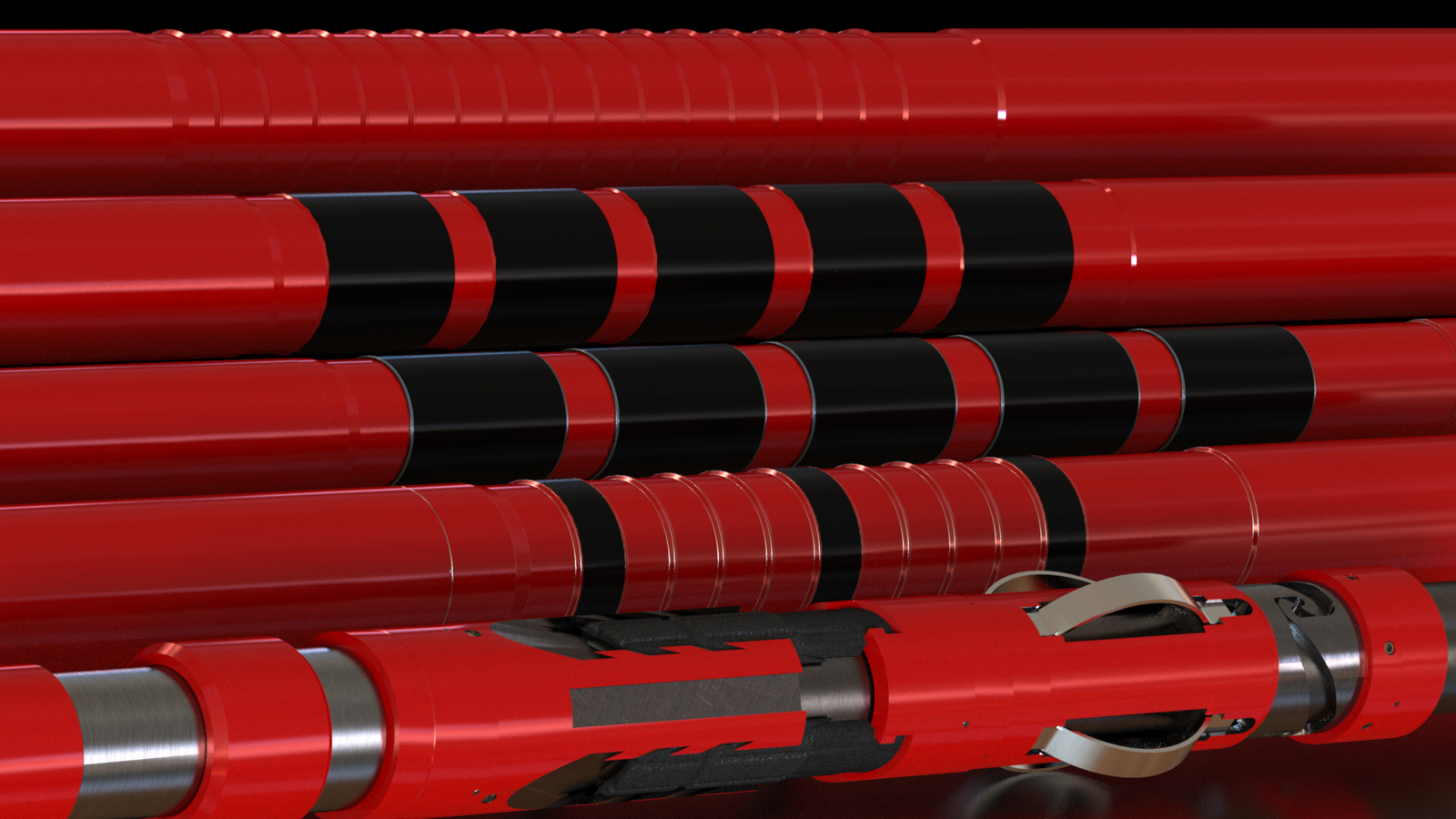

VersaFlex expandable liner hanger system, featuring:

An operator in Uzbekistan was drilling its first exploration well in a major gas field that was expected to contain over 100 billion cubic meters of gas. During the initial well construction stage, the operator encountered gas migration issues across a competitor’s conventional liner-top packer. The operator needed a reliable gastight, liner-top solution that would provide a positive seal to prevent gas migrations and avoid formation breakdowns.

Running liner hanger operations in high-pressure gas wells is challenging, as the liner must be able to reach target depth and provide the capability to rotate and reciprocate the liner string during the cement job. This creates turbulent flow during the cement displacement, which improves the slurry bond and placement, while minimizing potential channeling and migration of gas. Once the cement is displaced, a gas-tight, liner-top packer is required to secure the liner top and provide competent isolation for the life of the well.

7 x 9-5/8-in. VesaFlex system in Uzbekistan

health, safety, and environmental (HSE) issues

non-productive time (NPT)

The operator faced the challenge of gas leakage from a competitor’s liner-top packer and was looking for a robust liner hanger isolation system that would optimize cement integrity and wellbore stability in this complex well condition.

Halliburton proposed the VersaFlex® expandable liner hanger system as a solution for the operator’s first exploration well. The liner hanger assembly was built and exported from Kazakhstan to Uzbekistan. In parallel, the Cementing team designed the cement slurry based on the operator’s requirements and cemented the 7-inch liner casing.

Halliburton successfully deployed the first 7 x 9-5/8-inch VersaFlex system in Uzbekistan, which helped the operator prevent a costly remedial operation. The VersaFlex tieback seal assembly was run in hole with the 7-inch production casing and cemented to the surface. The installation was completed with zero non-productive time (NPT) and without any service quality or HSE issues.

With the highest reliability performance rating in the industry, the VersaFlex system helped Halliburton set a benchmark with its first installation in Uzbekistan.

Liner Hangers

The Halliburton VersaFlex ELH system is the industry’s first fully engineered ELH system designed for use in land, offshore and deepwater applications.

Download Data Sheet

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.