Search

Search

Search

Search

Single-trip logging run avoids expensive workover and minimizes rig time

Download PDFMature Fields

Conduct a detailed investigation to verify casing integrity

Land Operations, Denmark

Halliburton had carried out several casing integrity measurements over the past two years for an underground gas storage company in Denmark. As the main wireline provider, Halliburton had successfully used Xaminer® Electromagnetic Corrosion Tool (XECT) and Multifinger Imaging Tool (MIT) technology to verify casing integrity. This provided acceptable evaluation in 9 5⁄8-in. casing, but would require two separate runs.

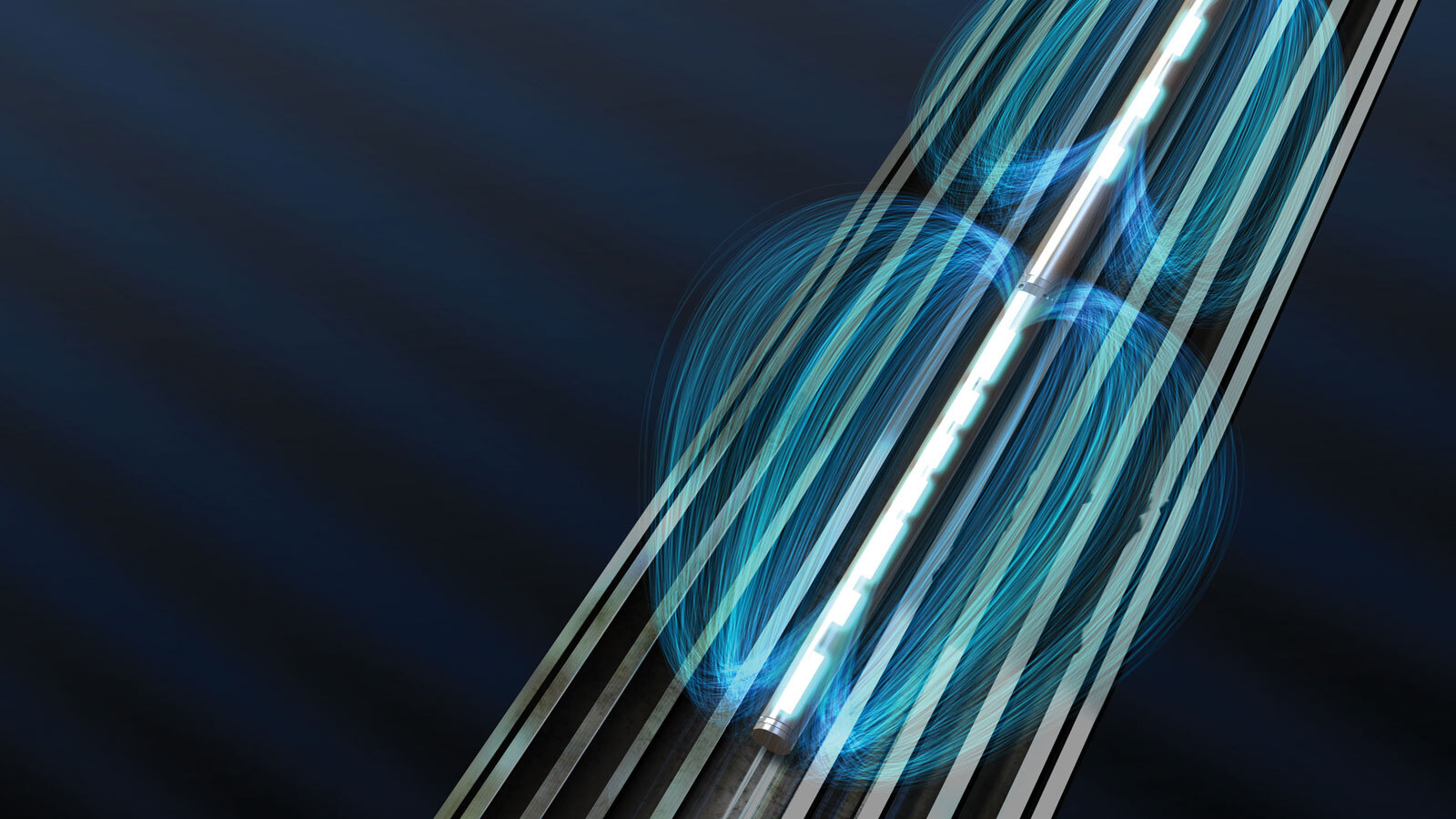

With the introduction of the new Electromagnetic Pipe Xaminer® V (EPX™ V) tool, Halliburton is able to evaluate up to five strings of casing, including in this instance 13 3⁄8-in. casing. With its combinability with MIT technology, a detailed investigation of the casing was achieved in one run.

Previously, the customer had been unable to evaluate the casing integrity of a second string (13 3⁄8 in.) in its gas storage caverns. The ability to complete everything in one day was a critical requirement. With pressure-control equipment rig ups and two to three runs of wireline, casing integrity checks can often take more than one day to be completed.

Halliburton proposed the use of the EPX V/MIT tool string to log the internal condition of the 9 5⁄8-in. casing and provide the overall condition of 9 5⁄8-in. and 13 3⁄8-in. casing in one run. This new tool combination would allow single-trip deployment where previous deployments had entailed two trips and were unable to evaluate the 13 3⁄8-in. casing. Additionally, the tool’s slim housing (1 11⁄16-in. OD) permits through-tubing access, offering an extended range of operation for quantitative analysis of up to five tubulars from 2 3⁄8 to 24 in. OD pipe.

Day saved

USD saved

The Halliburton casing integrity tool string (EPX V/MIT tools) was able to successfully identify the casing integrity on two strings in a single run, which included a full joint analysis of the initial 9 5⁄8-in. casing (MIT) and casing thickness and corrosion evaluation of both the 9 5⁄8- and 13 3⁄8-in. casing. This resulted in a time savings of one day and acquired integrity measurements on the outer string casing to prevent a costly workover operation, saving the customer approximately USD 25,000.

The customer was very appreciative that Halliburton could provide previously unavailable data and, with the combination run, reduce its logging time considerably.

The Halliburton EPX™ V accurately pinpoints casing defects and metal corrosion in up to five tubular strings throughout the well.