Search

Search

Search

Search

Horizontal pumping system rapid installation adds profit

Download PDFUnconventionals

Install a HPS for an operator's new saltwater injection station to add profits

Midland, Texas

An independent operator out of Midland, TX needed a horizontal pumping system (HPS) for its new saltwater injection station. Until the station was functional, the operator would have to either delay production or pay trucking fees for saltwater disposal. The operator did not want to wait the quoted 12 weeks for HPS delivery from their current supplier.

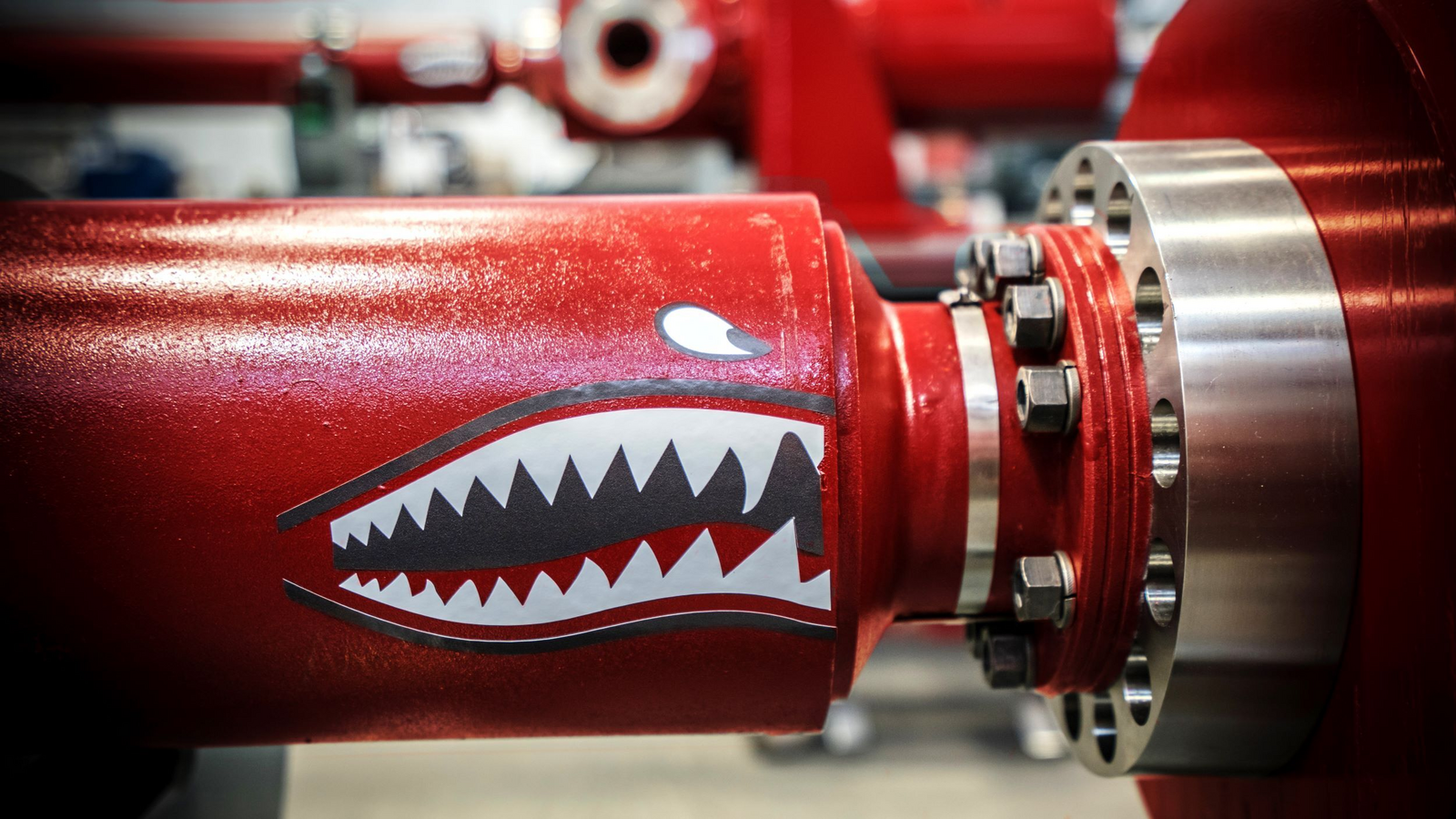

With a constant focus on customer needs and an agility unmatched by the large, traditional suppliers, Summit ESP® – a Halliburton service quoted a delivery time of six weeks and won the business. The Hercules™ horizontal pumping system is an efficient alternative to positive-displacement, split-case, and other surface pumping systems, offering longer run life and lower maintenance costs.

True to its commitment, Summit ESP delivered and installed the Hercules system on time. For the customer, the value of Summit ESP’s rapid response was significant. With oil production averaging 280 BOPD, our solution avoided $470,000 of deferred revenue (at $40/Barrel). With saltwater production averaging 5,600 BPD, the solution delivered an incremental $235,000 in profit over trucking in the first six weeks.

USD in Profit Over Trucking in the First Six Weeks

USD Deferred Revenue Avoided

Hercules™ horizontal pumping systems (HPS) are an alternative to positive displacement, split-case, and other surface pumping options.

Pump more efficiently with a focus on lower maintenance costs, longer operational life, and 24/7 monitoring.

Halliburton delivers superior performance and reliability by combining our proven products and decades of experience in artificial lift.