Search

Search

Search

Search

Increased reservoir exposure and reduced overall cost per BOE

Download PDFDeep Water

Overcome slot restrictions to enable further economic production

Norway

Retrofit multilateral technology allows operators to access new targets and produce from existing wellbores while maintaining production of the original slots with still viable economics. During retrofit multilateral well construction, the existing mainbore is temporarily plugged to allow drilling of an additional branch. After re-completing the well, the existing mainbore and the new branch are produced commingled, with inflow control valves regulating the flow from each branch.

Using proven reliable technology, Halliburton developed a retrofit multilateral solution for a North Sea operator to address various challenges and extend the productive life of mature fields.

The lack of slots available to drill new wells challenged the operator to introduce new well designs and technical solutions. The operator needed the ability to retrofit existing productive horizontal wells into multilaterals to increase reservoir exposure.

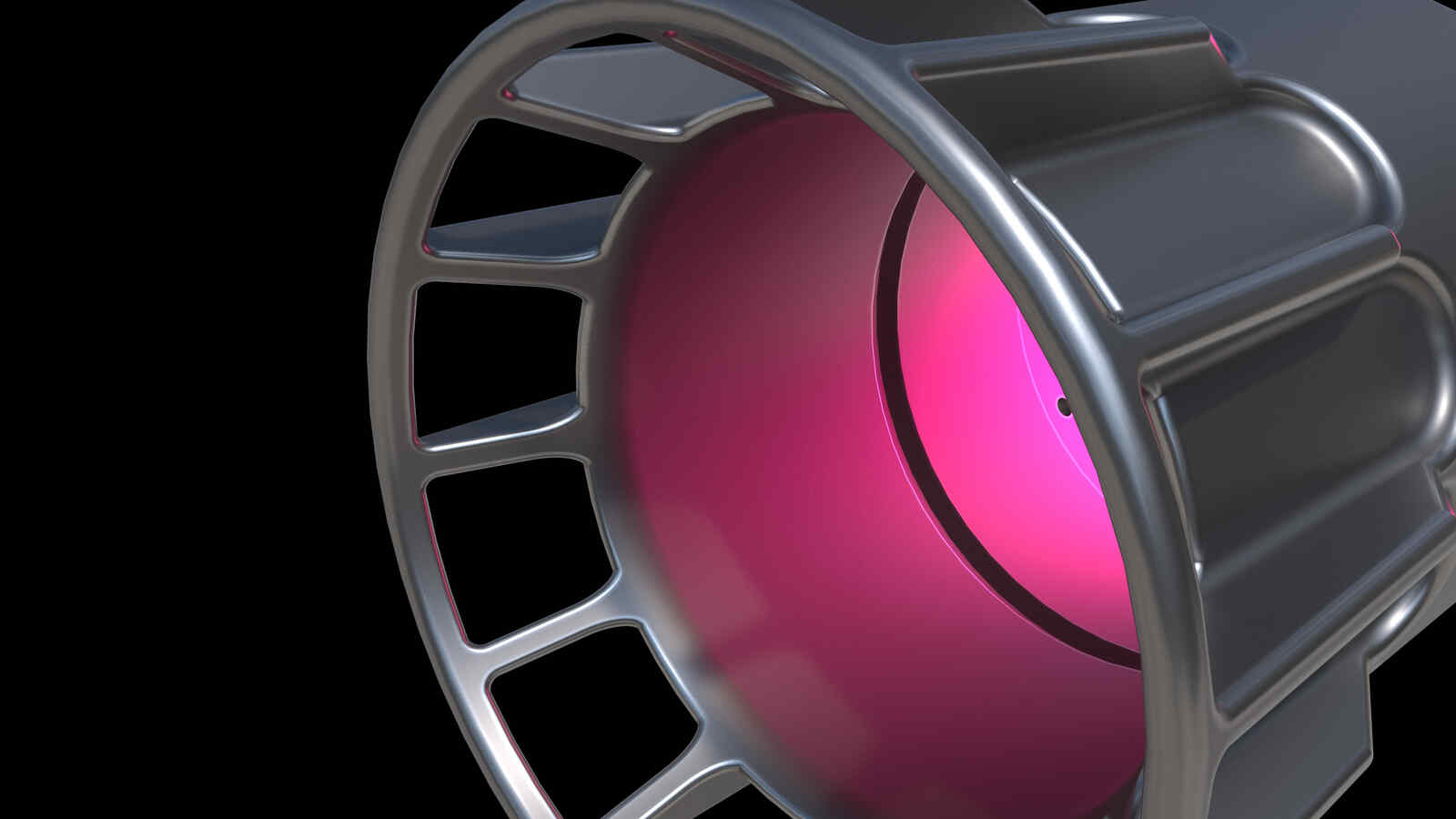

Halliburton recommended a retrofit multilateral installation that included the award-winning 9 5/8-inch FlexRite® multibranch inflow control (MIC) junction system and ReFlexRite® completion system. This combination allows the operator to mill a window in the existing mainbore casing for drilling and completing a new lateral branch to access a new production target. In addition, the FlexRite MIC junction system allows the branches to be flow controlled separately through interval control valves (ICVs).

The XtremeGrip MLT anchor packer provides a reliable foundation and completion flexibility to drill and complete the lateral junction. The Halliburton liner deployment system (LDS) is used to install the lateral completion with standalone screens (SAS) and swellable packers.

During operations, the existing mainbore was temporarily plugged while drilling the additional branch. After re-completing the well, the existing mainbore and the new branch produced commingled, with ICVs regulating flow from each branch.

lateral branches with intelligent flow control

operational days saved

related to mlt operations

Halliburton successfully completed the operator’s candidate well as a retrofit multilateral in late 2020. The Norway team delivered the well 4.9 days ahead of schedule, with zero non-productive time (NPT) related to multilateral operations, and all branches producing as expected. The XtremeGrip MLT anchor packer provided the necessary reference point for lateral construction and enabled installation of the FlexRite MIC junction. The retrofit multilateral installation helped increase reservoir exposure for the field, provided branch control of multiple laterals from the 9 5/8-inch casing, and maximized production from each multilateral leg — contributing significantly to reduced overall cost per barrel of oil equivalent (BOE) and maximizing asset value.

Visit FlexRite and ReFlexRite product information to learn more.

Data Sheet

ReFlexRite System

FlexRite® MIC System

Meritorious Award for Engineering Innovation Exploration and Production E&P Magazine (2014)

Download Data Sheet

FlexRite® System

The FlexRite® system includes a host of variants, extending its capabilities into intelligent completions, long lateral liner deployments and existing well re-entry applications.

Download MLT catalog