Search

Search

Search

Search

Downhole measurements were used to understand weight transfer from surface to downhole in lateral production section and how it impacts bit performance

Download PDFUnconventionals

Understand weight transfer from surface to downhole in lateral section

Permian Basin

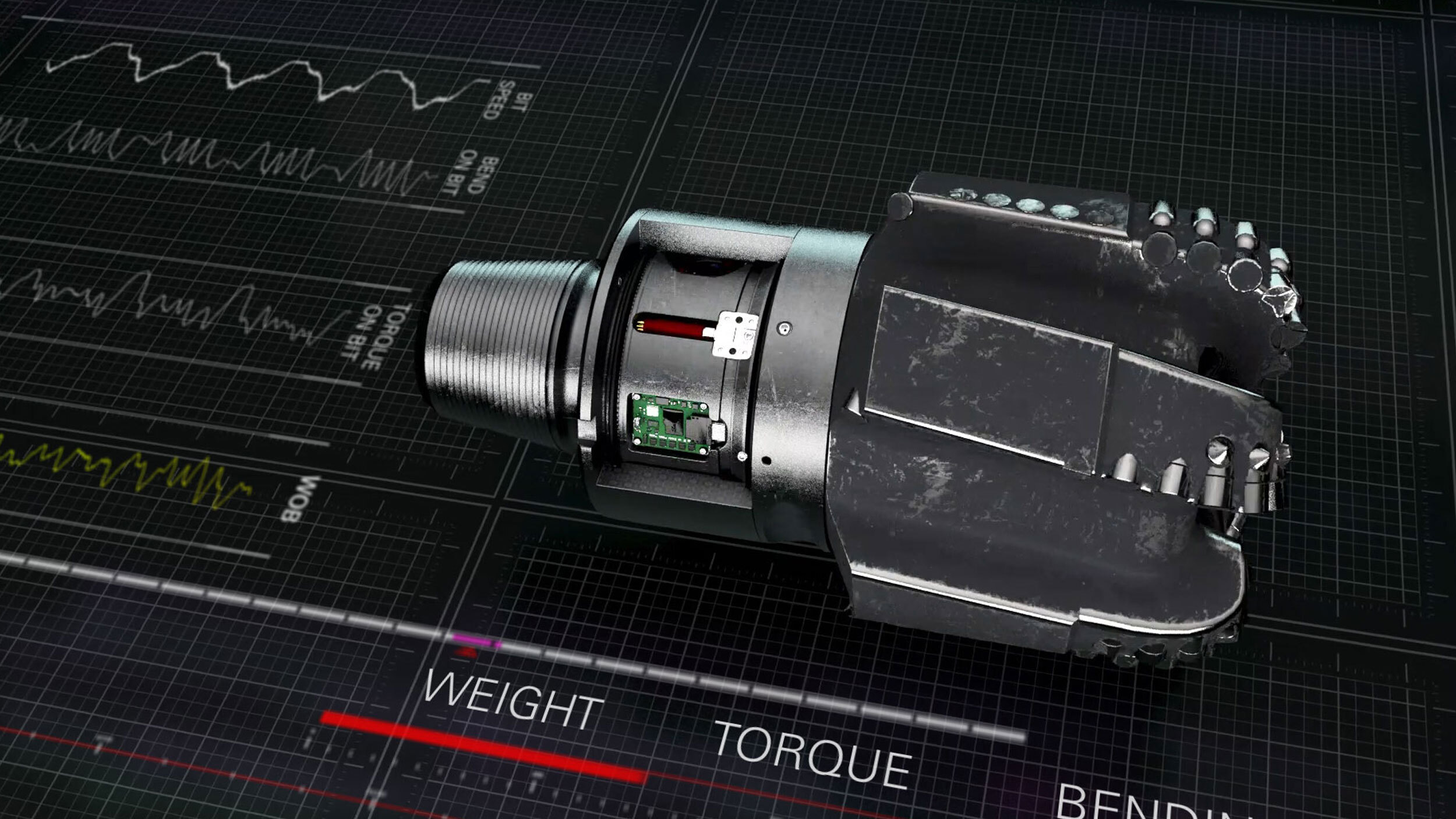

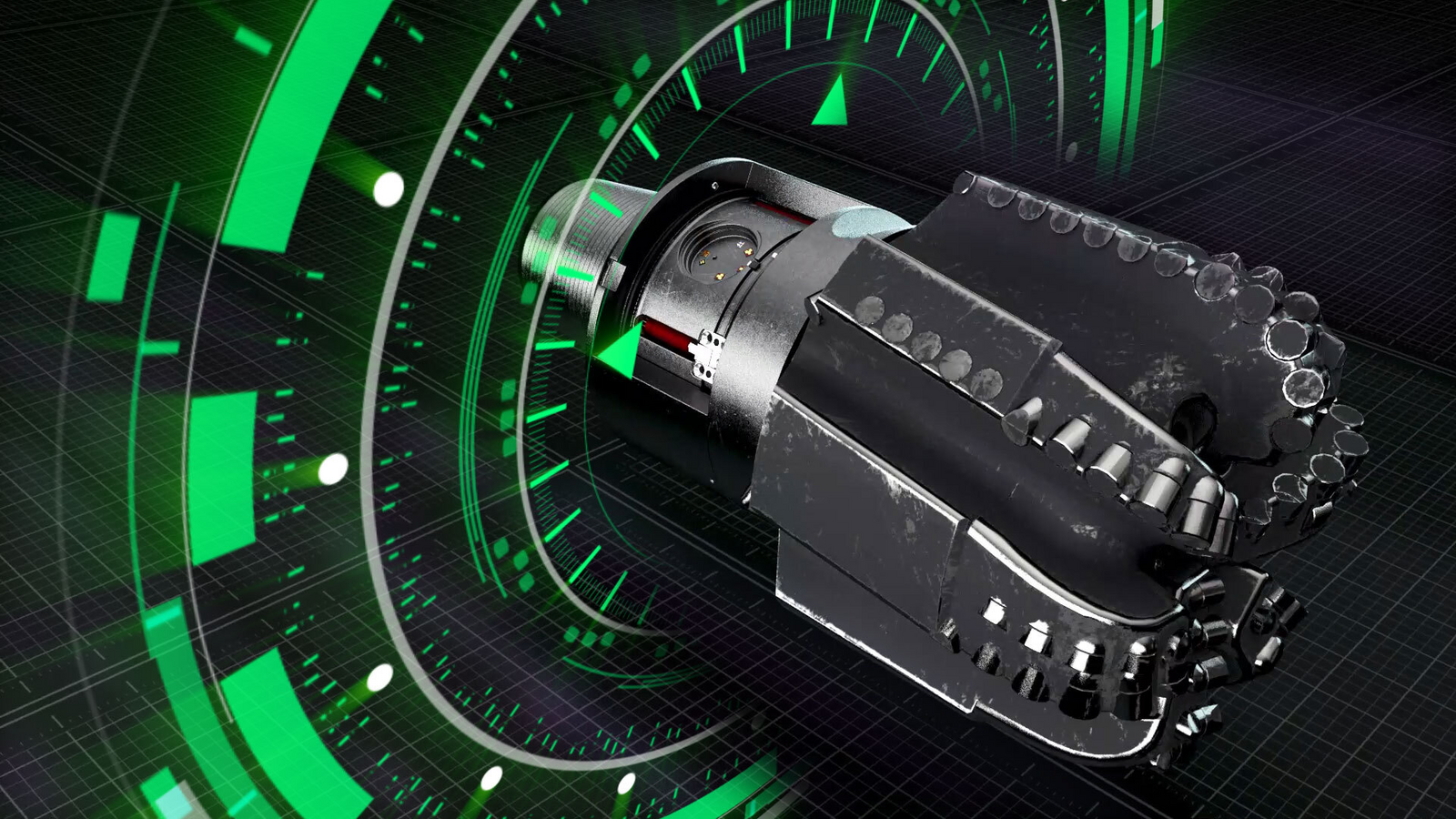

When drilling a lateral production section in an unconventional well, an operator wanted to determine how much weight and torque were effectively being transferred from the surface to bit, the associated downhole dysfunction, and how this affected performance. Cerebro Force™ in-bit sensing and its high-frequency 1,024-Hz in-bit downhole measurements were used to understand these factors, improve drilling practices, and ultimately improve overall performance in the lateral section.

Cerebro Force in-bit sensing was used to analyze drill bit behavior variances with the auto-driller control set to weight on bit (WOB) mode versus rate of penetration (ROP) mode. Lateral intervals were drilled within the same Third Bone Spring target formation, on the same pad, by the same drilling rig, using an 8-1/2 in. polycrystalline diamond compact (PDC) drill bit and a rotary steerable system (RSS) in conjunction with a positive displacement motor (PDM) as a combined drive system.

Higher dysfunction (axial, lateral, and torsional vibration) was observed in WOB control mode versus ROP mode. Therefore, ROP mode was recommended in addition to a higher ROP setting. In ROP control mode, similar vibration levels were observed, but at an overall higher ROP, and the dull condition of the drill bit was also improved. As a result, when the optimized drilling practices learned from these runs were applied, a 20% overall increase in ROP was achieved in addition to improved bit condition.

To help develop mitigation strategies and improve lateral drilling efficiency, an operator sought to understand weight transfer from the surface to downhole, variances in drilling behavior using two different auto-driller modes, and pertinent downhole dysfunction.

Cerebro Force in-bit sensing was run with auto-driller control settings in WOB and ROP mode to compare and identify higher dysfunctions in axial, lateral, and torsional directions. High-frequency data (1,024-Hz revealed that drilling in ROP mode at a setpoint of 150 ft./hr. created lower magnitude in axial, lateral, and torsional vibration compared to drilling in WOB mode at a setpoint of 35k lb.

Stands drilled in WOB control mode at a setpoint of 35k lb. exhibited steady surface WOB and varying instantaneous ROP, which, in turn, caused varying depth of cut (DOC). The ROP observations were consistent with downhole WOB observations measured by Cerebro Force in-bit sensing. It was also observed that, while drilling off WOB at the surface and downhole, WOB diverged when the tool joints passed through the rotating head.

In contrast, stands drilled in ROP mode at a setpoint of 150 ft./hr. exhibited steady ROP and consistent DOC, resulting in less dysfunction. Drilling in ROP mode delivered a consistent downhole WOB by applying more surface WOB while drill pipe joints passed through the rotating head.

During subsequent runs, based on the observations gleaned using Cerebro Force in-bit sensing, the auto-driller was set to ROP mode at a higher setpoint of 180 ft./hr. to help mitigate dysfunction, prolong tool life (drill bit, PDM, RSS, and other BHA components), and improve drilling efficiency.

Using at-bit weight measurements provided by Cerebro Force in-bit sensing, the operator was able to optimize the auto-driller control mode and set points, which engaged the PDC cutting structure at a constant DOC. This increased on-bottom ROP by 20% while improving dull conditions by mitigating harmful dysfunctions that can arise from conditions with variable DOC.

The Halliburton Cerebro Force™ in-bit sensor improves drill bit performance, giving operators data needed to optimize use for the length of a run.