Search

Search

Search

Search

UAE offshore exploratory well successfully completed with four different cemented liner sizes

Download PDFDeep Water

Complex wellbore design

Arabic Gulf

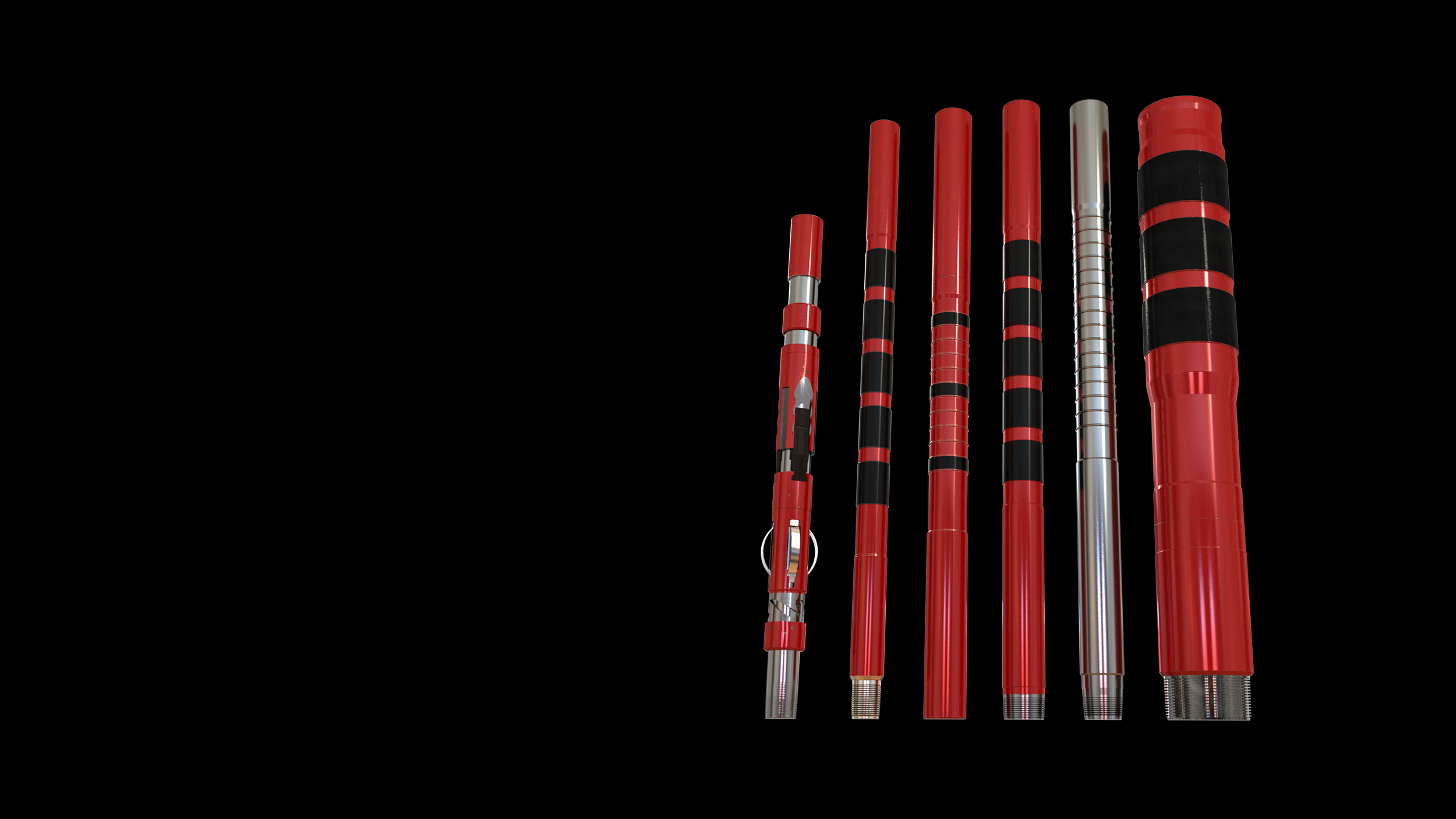

An offshore well was drilled to a depth of more than 20,000 ft to allow the operator to explore several zones of interest from a single wellbore. During the design and execution phases, multiple liner hanger systems were deployed to reach the required depth without jeopardizing the overarching design. Due to the challenging sour environment and complex design, the VersaFlex® expandable liner hanger (ELH) and XtremeGrip® ELH systems were selected for the job.

The final design required four sections to be isolated with cemented liners. Each section presented potential operational issues that required ELHs with unique capabilities.

A salt formation with movable sands was encountered during the drilling phase. Movable sands are known to pose operational issues related to well control, kicks, and tight spots.

After the 16-in. shoe was drilled, the hole section exhibited balloon effects, which were quickly controlled. The remaining part of the hole section was drilled without any issues. Although no significant liner-deployment challenges were expected, standard expandable liner hanger (ELH) protocol necessitated pre-job planning and risk mitigation.

This section was considered the most challenging due to the depleted Wasia formation. It required drilling through the formation and installing an intermediate liner to isolate the wellbore and prevent compromise of subsequent sections. Depleted zones often present operational challenges related to differential sticking, excessive fluid loss, and potential well control.

This hole section involved drilling through the Nahr Umr, Thamama, and Salld/Rayda formations. At 16,939 feet, hard rock was encountered, prompting a reduction in hole size from a 12 1/4-inch reamer to a 10 5/8-inch bit. Similar to Section 2, no significant liner deployment challenges were observed; however, standard expandable liner hanger (ELH) protocol required pre-job planning and risk mitigation.

The following provides an overview of each hole section and outlines the highlights of the ELH system installation and the solutions provided.

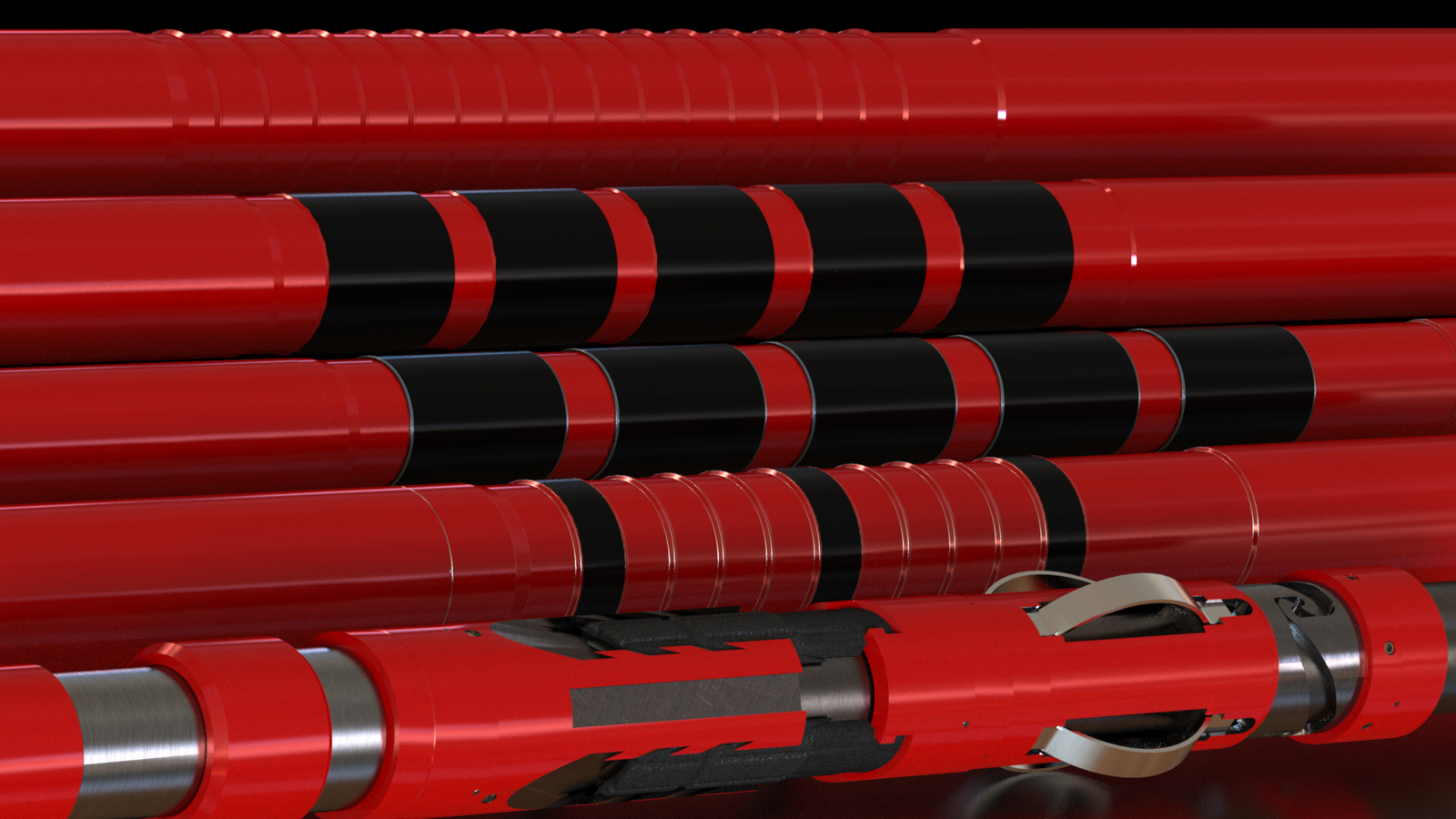

Section 1: A 16- × 20-in. VersaFlex® Big Bore ELH system was deployed into the well, passing 75 tight spots along 5,830 ft (1777 m) of openhole section. Auto-fill float equipment minimized surge/swab effects. Liner cement procedures proceeded as planned, and the liner hanger was successfully set, tested, and retrieved.

Section 2: A 13 5/8- × 16-in. VersaFlex Big Bore ELH system with a 20-foot upper tieback receptacle (TBR) was deployed into the well. Auto-fill float equipment minimized surge/swab effects. Liner cement procedures proceeded as planned with 10% excess above the top of the liner (TOL). The liner hanger was set, tested, and the run tool was released; however, it required additional time, multiple attempts, and excessive slack-off weight (SOW) before successful retrieval.

Section 3: An 11 3/4- × 13 5/8-in. XtremeGrip® ELH system was deployed into the well. The last 377 ft (115 m) required hard reaming to reach the required depth. Auto-fill float equipment was used to help minimize surge/swab effects in the tight-clearance application. The liner cement design was modified to align with the static thickening time of the slurry and additional time was allowed for circulation. The liner hanger was set and tested. A run tool was released after additional slack-off force was applied and successfully retrieved.

Section 4: A 9 5/8- × 13 5/8-in. XtremeGrip ELH system with a 20-ft lower polished bore receptacle (PBR) at an overall length of 90 ft (27.7 m) was deployed into the well without issue. Auto-fill float equipment was used to help minimize surge/swab effects. Lessons from previous sections informed the cement design, which proceeded as planned. The liner hanger was successfully set, tested, and the run tool retrieved at the surface.

hole-section challenges overcome

HSE issues

service quality issues

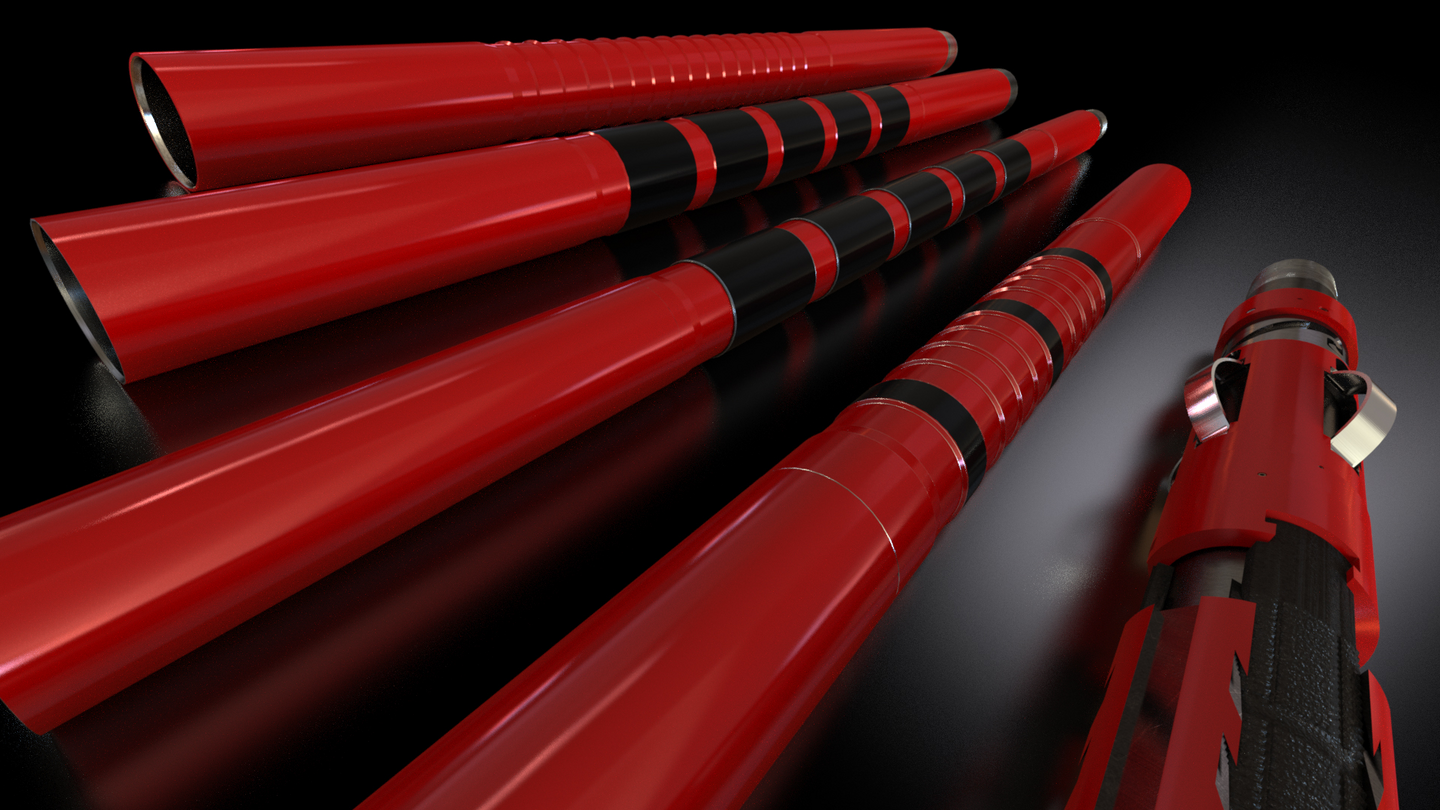

Both the VersaFlex and XtremeGrip ELH systems enabled the operator to reach the required depth, successfully set the liner hangers, and execute cementing, even in the presence of a complex well profile. Design characteristics of both ELH systems confirmed the following advantages:

The VersaFlex and XtremeGrip ELH systems helped overcome a variety of issues (over multiple hole sections with significantly distinctive characteristics) without the risk of presetting or pre-releasing. The technology and services provided a sealed liner top that followed a preplanned design, which was adjusted as lessons were learned to help mitigate potential risks. No HSE or service quality incidents were encountered, and each hole section was completed efficiently and on time.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.