Search

Search

Search

Search

First Installation of Big Bore in Bolivia, and first deployment of system on land in Latin America

Download PDFMature Fields

Install a blowout preventer (BOP) before drilling an exploratory well

Santa Cruz, Bolivia

In the Sub-Andean zone of Bolivia, TOTAL E&P Bolivie was drilling an exploratory well of high complexity because of intercalations of hard and abrasive formations. Due to a possible area with hydrocarbons in an upper stage of the well, the 20-inch casing needed to be set at a higher depth than in the offset wells in order to install a blowout preventer (BOP) before entering this zone, thus providing a safer operation. Additionally, a 16-inch, gas-tight liner hanger had to be included in the architecture of the well to cover part of the carboniferous formation.

TOTAL E&P Bolivie needed a globally proven, yet simple, technology that could reliably set a 16-inch liner hanger in just one trip to enable the installation of the BOP stack. The necessary equipment for this operation had to be able to support a long string (500-2,000 meters/1,640-6,561 feet of liner), along with a high amount of weight (140-550 kips/140,000- 550,000 lb). Additionally, this equipment had to be expediently delivered to the site in order to meet crucial project deadlines.

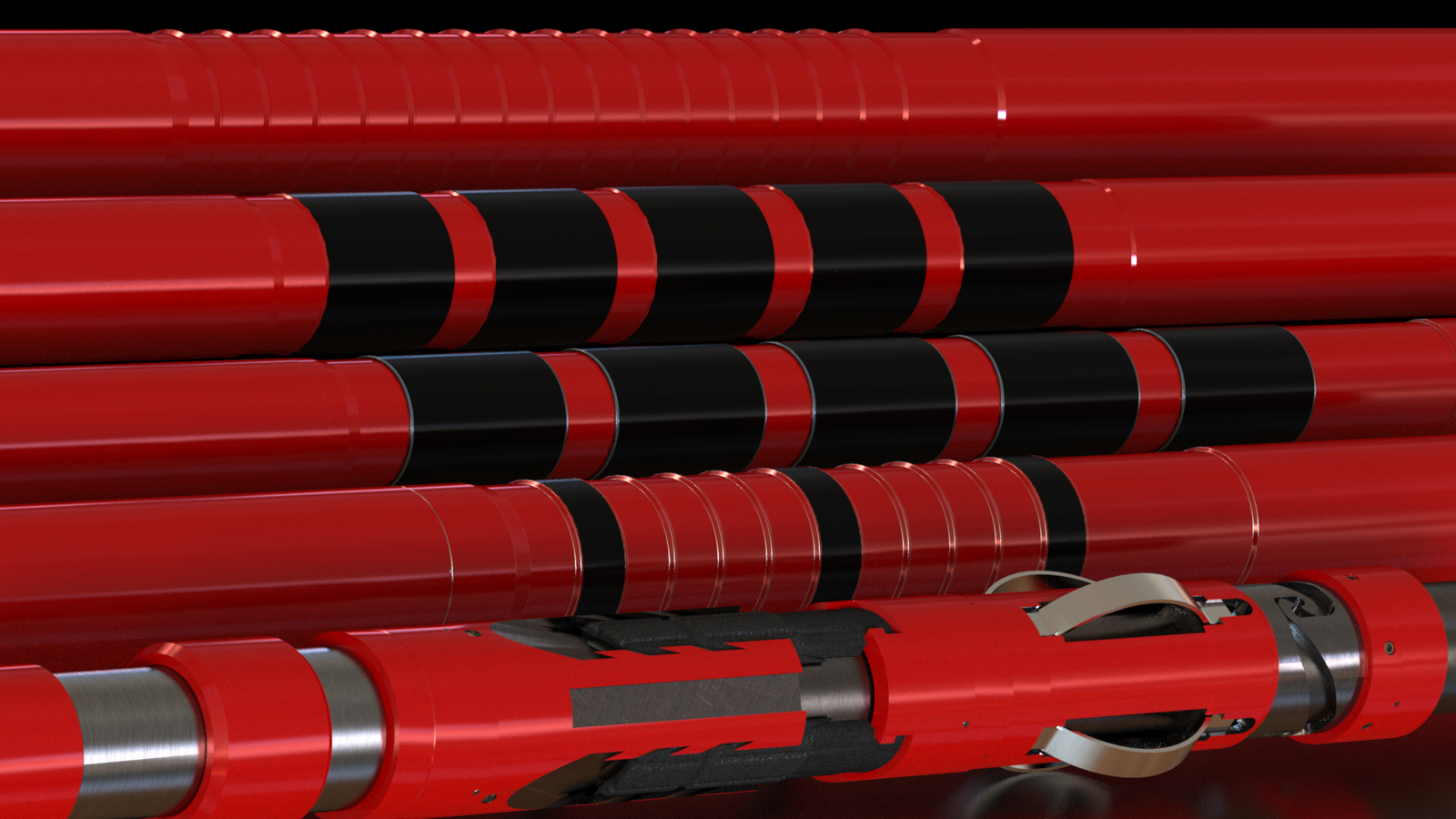

The Halliburton VersaFlex Big Bore expandable liner hanger system was a natural fit for this application because it is designed to provide both a liner-top packer and an expandable liner hanger in a single trip. The system’s smooth-form exterior allows the hanger to move safely through tight tolerances and casing anomalies. Multiple sealing elements were preferred over the delicate external moving parts and single-sealing element of the casing hanger. The VersaFlex Big Bore running tool and hanger are designed to robustly withstand the predicted length and weight of any possible scenario during the drilling phase of a well, and to still have the ability to wash, ream, or drill the liner into position.

Originally designed specifically for deepwater and subsea markets, the VersaFlex Big Bore system is ideal for complex well conditions. It does not require landing in a predetermined profile, thus mitigating complications common to positioning in mudline/casing wellhead profiles. The VersaFlex Big Bore system is an all-in-one integral hanger/packer system with no moving parts, which reduces the costly tool failures associated with conventional liner hangers. The system’s simplistic design minimizes the operating steps that are typically required to set conventional liner hangers/packers – virtually eliminating remediation costs.

ft measured depth (MD) drilled in one run

trip installation

NPT

For TOTAL, after the drilling phase for this section was over, the VersaFlex Big Bore system was successfully run to 2,495 meters (8,186 feet) measured depth (MD) in one trip. The system was deployed without any safety or service quality issues – and, most importantly, without any non-productive time (NPT).

With its exceptional reliability performance rating, the VersaFlex Big Bore system helped Halliburton achieve a benchmark for the system’s first installation in Bolivia, and also for the first VersaFlex Big Bore liner hanger deployment in an oil or gas well on land in Latin America.

Liner Hangers

The VersaFlex Big Bore system is designed specifically for the deepwater and subsea markets to address complex well conditions.

Download Data Sheet

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.