Search

Search

Search

Search

Flawless deepwater ELH installation in Egypt delivers multiple regional records and global firsts

Download PDFDeep Water

Extend deepwater operating envelope in the Mediterranean Sea

Deepwater Mediterranean Sea

An operator had a challenging well design for an exploratory high-pressure/high-temperature (HP/HT) well located in deep water in the Mediterranean Sea. Well construction operations were to be completed by utilizing a deepwater-capable dual-derrick drillship that had a high hourly operating rate, so minimizing rig time was an important factor for these operations.

The well design required drilling a long, large-bore openhole interval of 6,562 feet (2000 meters) before running an 18-inch liner through a low-strength, regressed sand formation. Managing annulus pressure buildup (APB) required this liner string to be only tack-cemented in order to isolate the pressured zone within this hole section. Planned total depth (TD) for the exploratory well was 20,433 feet (6228 meters) in a water depth of 3,363 feet (1025 meters).

In this low-strength sand, APB management required a robust liner system, using a tackcemented 18-inch x 22-inch liner top with no leak paths (i.e., no hydraulic cylinder and associated seals) in order to provide the necessary liner-top integrity with minimal impact to rig time. A kick during drilling operations at 7,201 feet (2195 meters) – 180 feet (55 meters) out of the 22-inch casing shoe – reaffirmed the well integrity risk and the requirement to adequately isolate the liner top without cement.

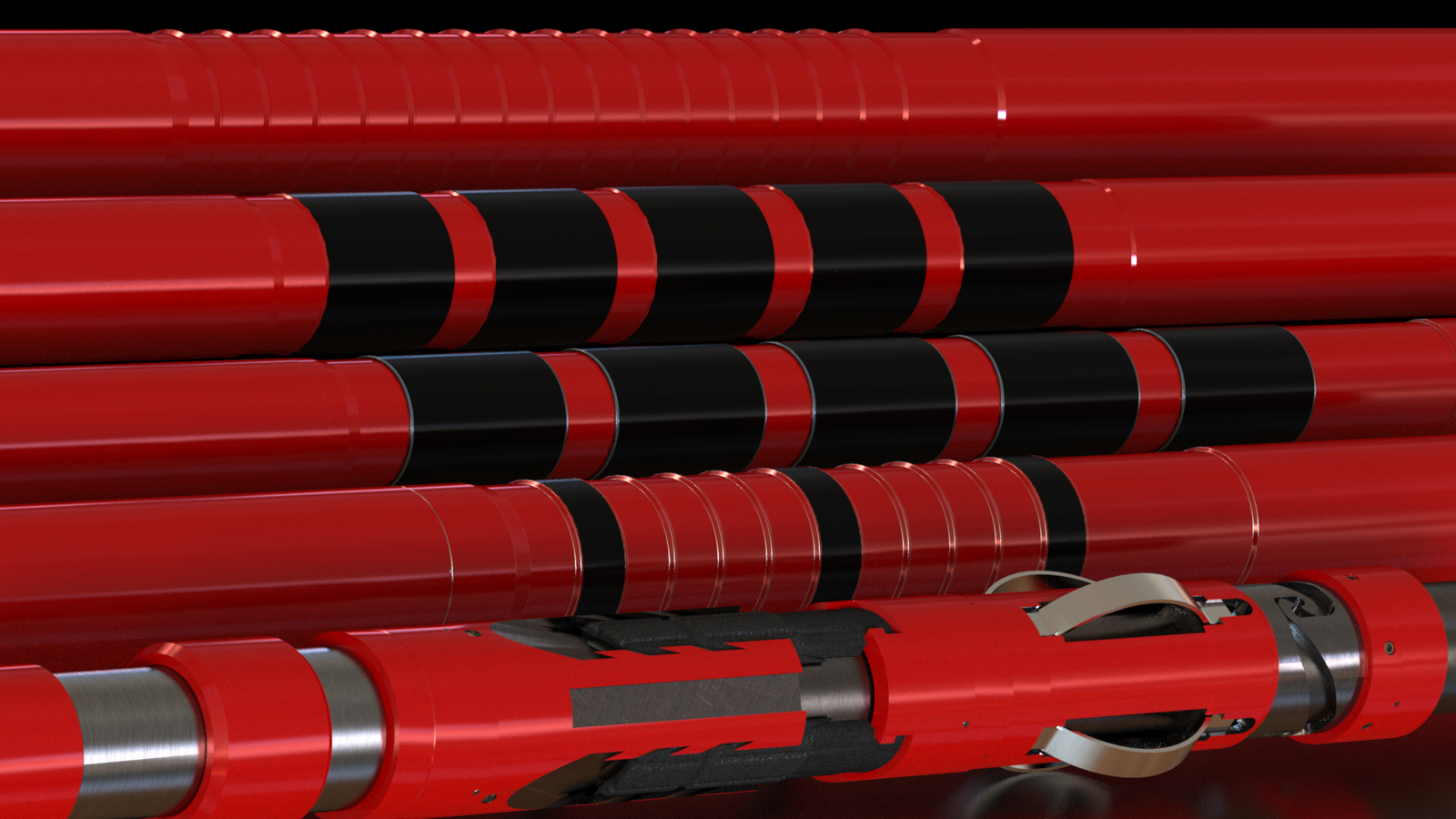

Halliburton recommended its 18-inch x 22-inch VersaFlex Big Bore expandable liner hanger (ELH) system, which could deploy the string to TD with the capability to circulate at high rates if required. The system could provide independent pressure integrity of the liner top, without relying on cement and without introducing additional potential leak paths that are common with conventional liner hanger systems. The VersaFlex Big Bore system has a liner-top sealing solution with all metal-tometal connections within the body and no activation ports or seals. Additionally, its companion running tool allows multiple immediate confirmations of packer setting, along with the ability for subsequent liner lap pressure tests. This saves rig time over standard liner operations that typically require running tools to be retrieved to surface for similar confirmations. The all-hydraulic activation of the VersaFlex Big Bore system has the added benefit of minimizing the need for heavyweight drillpipe to set the liner top, which is typically required in comparative big bore liner applications.

shoe installation - deepest in the Mediterranean Sea

ft. ELH installation

This was the first 18-inch x 22-inch VersaFlex Big Bore system installation for this global operator, and the success of this installation has resulted in new opportunities for this system in Egypt. To date, this was the longest ELH installation in the Mediterranean basin – approximately 13,123 feet (4000 meters). This liner hanger also had the deepest 18-inch shoe in the Mediterranean.

The positive hanger/packer setting indication provided during the setting operation enabled immediate liner-lap pressure tests. The pressured zone was successfully tack-cemented and isolated, allowing the operator to proceed with further wellbore construction operations while meeting APB management requirements. The VersaFlex Big Bore system provided liner-top integrity without cement, ensuring that there were no leak paths within the body of the liner hanger and enabling wellbore integrity tests to be performed without waiting on cement or retrieving running tools to surface.

Liner Hangers

The VersaFlex Big Bore system is designed specifically for the deepwater and subsea markets to address complex well conditions.

Download Data Sheet

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.