Search

Search

Search

Search

Operator saves $200k in rig time with no HSE or NPT

Download PDFDeep Water

Install liner hanger in pre-salt offshore deepwater well

Brazil, Latin America

A pre-salt offshore deepwater exploratory well in Brazil required a robust and efficient liner hanger system for the contingency salt reservoir section.

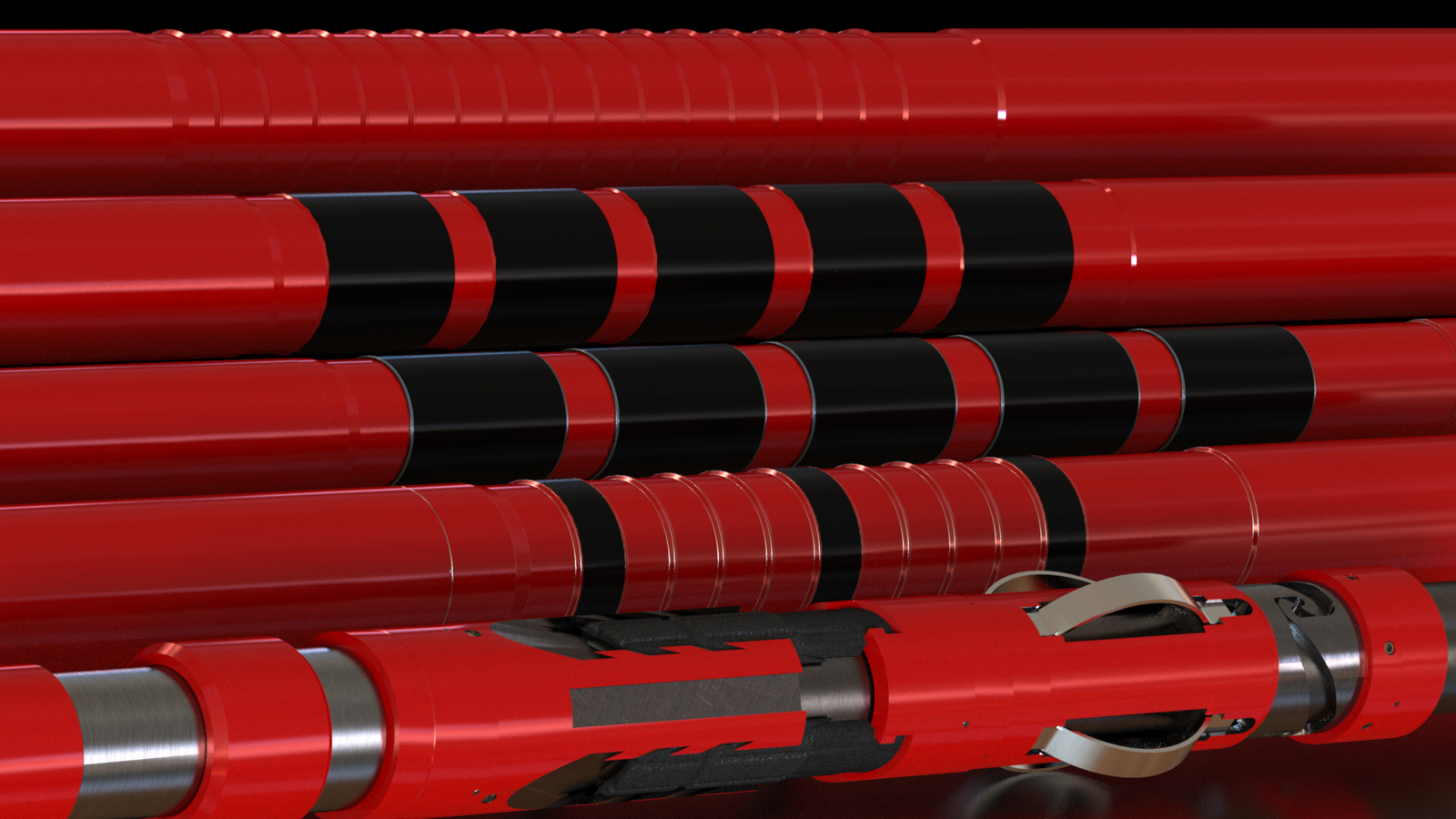

Halliburton used a single trip 11 7/8 x 14-in. VersaFlex expandable liner hanger system in conjunction with autofill Super Seal II float collar and float shoe.

The VersaFlex standard expandable liner hanger packer was expanded and set, providing effective zonal isolation on the top of the liner.

Repsol Sinopec was planning to drill an exploratory, deepwater well in the pre-salt reserves offshore Brazil and needed a robust and efficient liner hanger system for the contingency salt reservoir section. Halliburton proposed the single-trip 11 7/8 x 14-in. standard VersaFlex expandable liner hanger system in conjunction with the VersaFlex® wiper plug system, and a Super Seal II® float collar and float shoe pre-set to autofill.

Tools were mobilized in just 10 days, and experienced personnel—global and local—were on the scene in two days. The liner was rotated during the cementing job, and the VersaFlex standard expandable liner hanger packer was expanded and set, providing effective zonal isolation on the top of the liner.

Halliburton was able to save Repsol Sinopec more than $200,000 in rig time by completing the job 20 percent faster than the time allotted. This achievement marked a major milestone in another successful construction of this operator’s deepwater pre-salt exploration well in Brazil.

Repsol Sinopec was planning to drill an exploratory, deepwater well in the pre-salt reserves offshore Brazil and needed a robust and efficient liner hanger system for the contingency salt reservoir section. Because the well presented challenges such as short liners and tight clearance, the system needed to deliver smooth deployment with good equivalent circulating density (ECD) and better flow area, while still providing a reliable liner top gas-tight seal to isolate the salt section and land the liner shoe below the base of the salt section.

Halliburton proposed the single-trip 11 7/8 x 14-in. standard VersaFlex expandable liner hanger system in conjunction with the VersaFlex wiper plug system, and a Super Seal II float collar and float shoe pre-set to autofill.

Strict adherence to Halliburton HSE standards and 10 Life Rules enabled the crew to execute the operation in a safe manner. On the rig, several meetings with Repsol Sinopec were held to discuss the job as operations progressed. Before beginning each new task, team meetings were held, and each member of the crew was also required to fill out a daily safety card.

HSE

faster than allotted rig time

of rig-time savings

Tools were mobilized in just 10 days, and experienced global and local personnel were on the jobsite in two days. The liner was rotated during the cementing job, and the VersaFlex expandable liner hanger was expanded and set, providing effective zonal isolation on the top of the liner. This demonstrated our “set-and-forget reliability” and enabled the Repsol Sinopec to continue the well operations with minimal risk. The autofill shoe track helped while running in-hole, and provided a safe, efficient job operation. The operation was completed with ZERO health, safety and environmental issues.

Halliburton was able to save Repsol Sinopec over $200,000 in rig time by completing the job 20 percent faster than the time allotted. In addition, a major milestone was achieved: another successful construction of Repsol´s deepwater pre-salt exploration well in Brazil.

In a customer satisfaction survey, Repsol Sinopec noted that Halliburton demonstrated a professional contribution in pre-planning and execution. They also noted that the equipment worked exactly as planned.

Liner Hangers

The Halliburton VersaFlex® expandable liner hanger (ELH) system is the industry’s first fully engineered ELH system designed for use in land, offshore and deepwater applications.

Download Data Sheet

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.