Search

Search

Search

Search

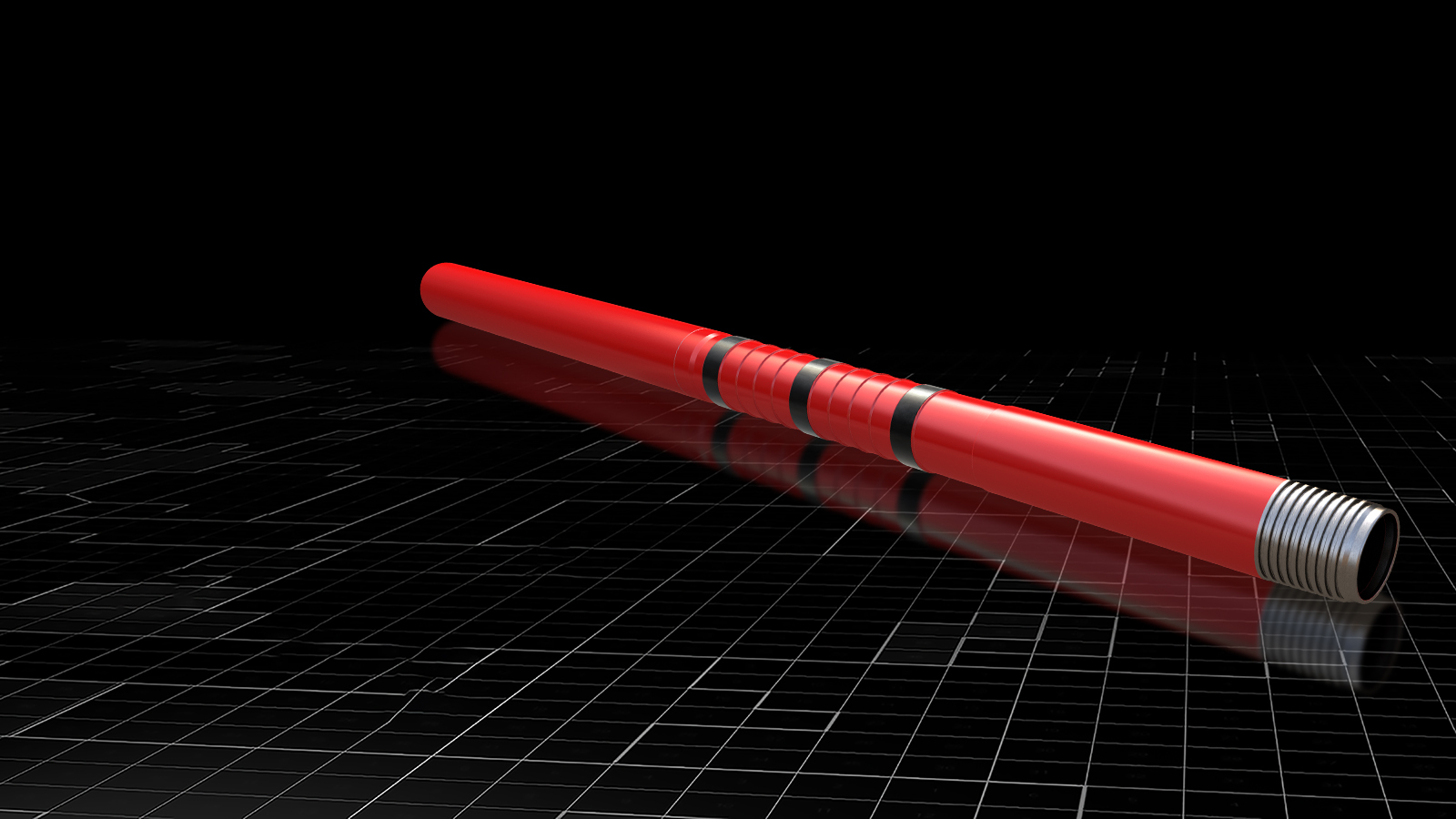

Pure metal-to-metal sealing technology overcomes challenging well conditions associated with elastomer seals

Download PDFContinuous Improvement

Abrasive material affected the compliance of the seal at TOL

Equador

Halliburton has successfully run the VersaFlex XSL standard expandable liner hanger system, which combines both metal-to-metal (MTM) and elastomeric seals, in Ecuador since 2018. However, continuous rotation to get the liner to depth and circulation of abrasive debris during these jobs affected elastomer seal performance and the ability to achieve a liner-top seal. The Liner Hangers team recognized an opportunity to improve the sealing technology and proposed a new design that removed all elastomers from the VersaFlex XSL hanger body. To prove the zero-elastomer design, the team performed validation testing of the engineered extrusion limiter spikes in a pure MTM sealing scenario without elastomeric backup seals. The test results provided the customer with confidence to field trial the VersaFlex XSL-ZE expandable liner hanger system to address the wellbore environmental challenges experienced during previous installations.

The Liner Hangers team collaborated with the customer to select an appropriate candidate well. The experienced workshop and field personnel in Ecuador prepared and installed the VersaFlex XSL-ZE system in a directional wellbore according to plan, which included rotation during the cementing job. The job was completed with zero non-productive time (NPT) or HSE incidents.

To achieve a reliable liner-top seal in the challenging well environment, the operater needed a liner hanger system with sealing elements that could withstand continuous rotation and circulation of abrasive debris-laden formation fluid.

After thorough analysis and exploration of various sealing options, Halliburton proposed the VersaFlex XSL-ZE expandable liner hanger system, which removes all resilient elastomers from the VersaFlex XSL hanger body and features rigorously tested, engineered interference ribs to provide full MTM sealing and anchoring. The zero-elastomer design mitigates wellbore environment compatibility issues and allows for higher temperature ratings to help ensure a reliable liner-top seal upon setting.

MTM sealing scenario

HSE issues

NPT issues

Halliburton successfully installed the VersaFlex® XSL-ZE system with zero NPT or HSE issues. The zero-elastomer design enabled rotation through tight spots and during cement displacement. Plus, the new sealing system successfully passed a rigorous 1,000-psi positive pressure test at the TOL, ensuring system integrity and confirming the effectiveness of the VersaFlex XSL-ZE system solution.

This important step change in anchoring and sealing technology proves the VersaFlex XSL-ZE expandable liner hanger can overcome abrasive well conditions and temperature limitations associated with elastomeric seals and widens the scope of application and deployment possibilities for liner hangers.

xsl-ze elh system

Zero-elastomer design highlights a major step change in expandable liner hanger sealing design and reliability

Download Data Sheet

Delivers a low-to-moderate load bearing without sacrificing its gas-tight sealing capability or reliability