Search

Search

Search

Search

12 rig-time hours saved during XtremeGrip ELH operations performed with zero service quality or HSE issues

Download PDFDeployment issues and gas migration

Offshore Vietnam

A major operator in Vietnam was developing high-pressure/high-temperature (HP/HT) offshore platforms for a high-profile project that included completion of eight gas condensate wells in two phases. The project required a system that could provide a positive seal to prevent gas migration after setting and formation breakdown during deployment. To address these challenges, Halliburton recommended and ultimately deployed the first 9 5/8-inch XtremeGrip Nickel 825 expandable liner hanger system, which saved the operator 12 hours of rig time. The Liner Hanger team performed all eight installations successfully, with zero health, safety and environment (HSE) or service quality issues.

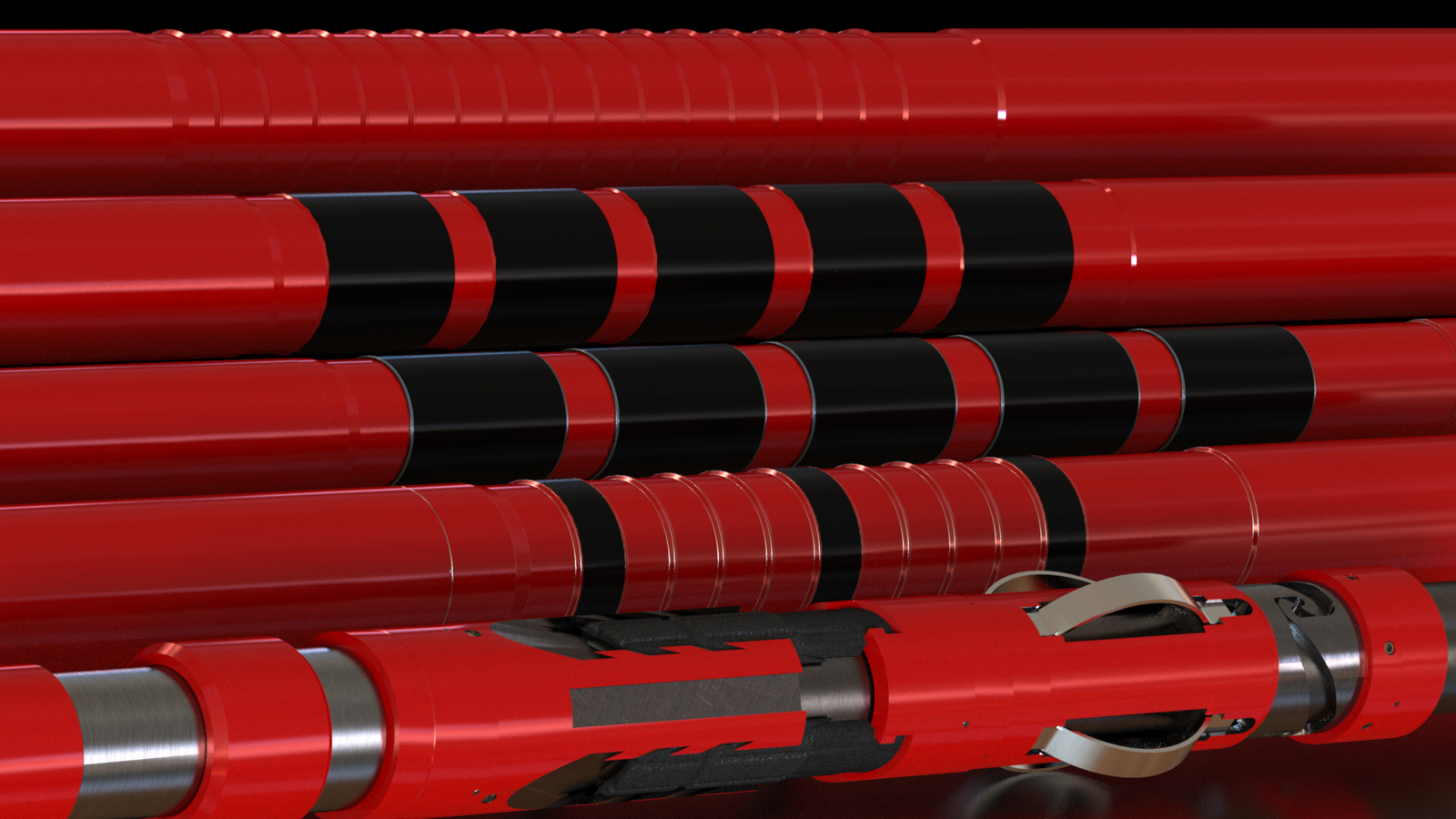

Liner hanger installations in HP/HT gas wells must provide reliable sealing and the ability to hold load for the life of the wells. A qualified, gas-tight, liner-top packer was necessary to secure the liner top and provide competent isolation during the wells’ life span.

Initially, the operator planned to use a competitor’s conventional liner hanger (CLH) system due to previous use during HP/HT projects in Vietnam. However, CLH system limitations presented issues. During pursuit of the project, Halliburton Liner Hanger representatives listened to the operator’s concerns and provided engineering specifications and an on-time delivery plan using an XtremeGrip expandable liner hanger solution.

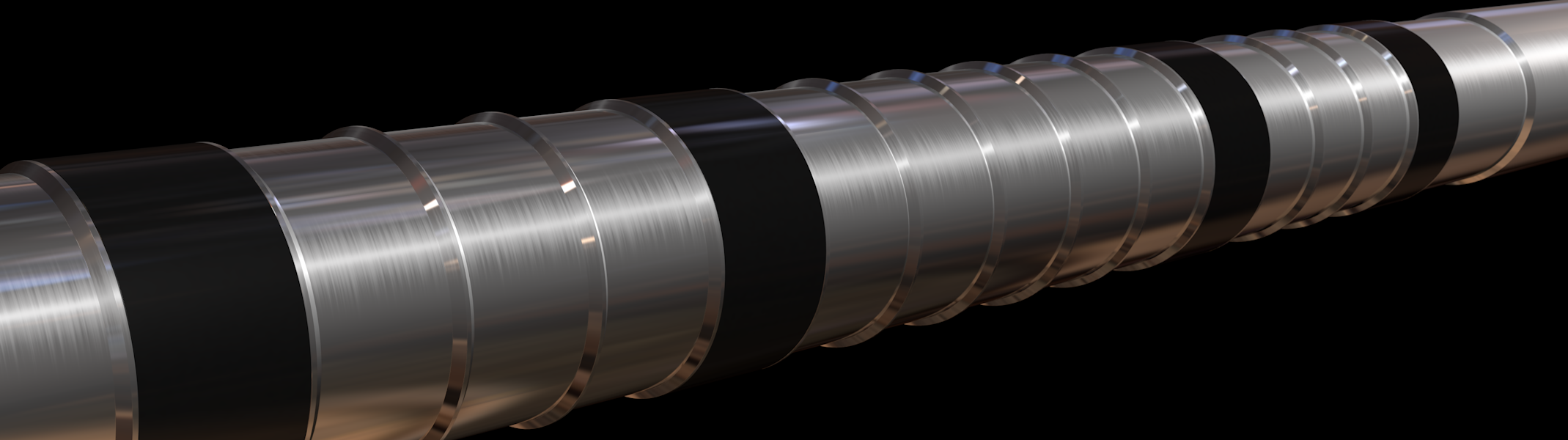

With hydraulically energized metal-to-metal anchoring and sealing capability, the XtremeGrip expandable liner hanger system addressed both sealing and long-term anchoring challenges.

hours rig time saved

wells successfully completed

NPT and HSE

Collaboration between Halliburton and the operator resulted in successful completion of all eight wells, with five XtremeGrip liner hanger well installations during Phase I and three well installations during Phase II.

Halliburton XtremeGrip expandable liner hanger technology helped the operator simplify liner hanger operations and maximize operation efficiency during this high-profile HP/HT project. The ability to deploy the flapper without requiring ball drop to set the liner hanger saved the operator approximately 1.5 hours of rig time per well (12 hours total). The Liner Hanger team deployed, cemented, set and sealed the XtremeGrip expandable liner hangers with zero non-productive time (NPT) and zero service quality or HSE issues, all during the COVID-19 pandemic. As a result, the operator plans to use the XtremeGrip expandable liner hanger system for the Phase III wells in 2024.

Data Sheet

High-performance metal-to-metal sealing technology ideal for complex deepwater wells and ultra-high temperatures for geothermal applications.

Product Information

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.