Search

Search

Search

Search

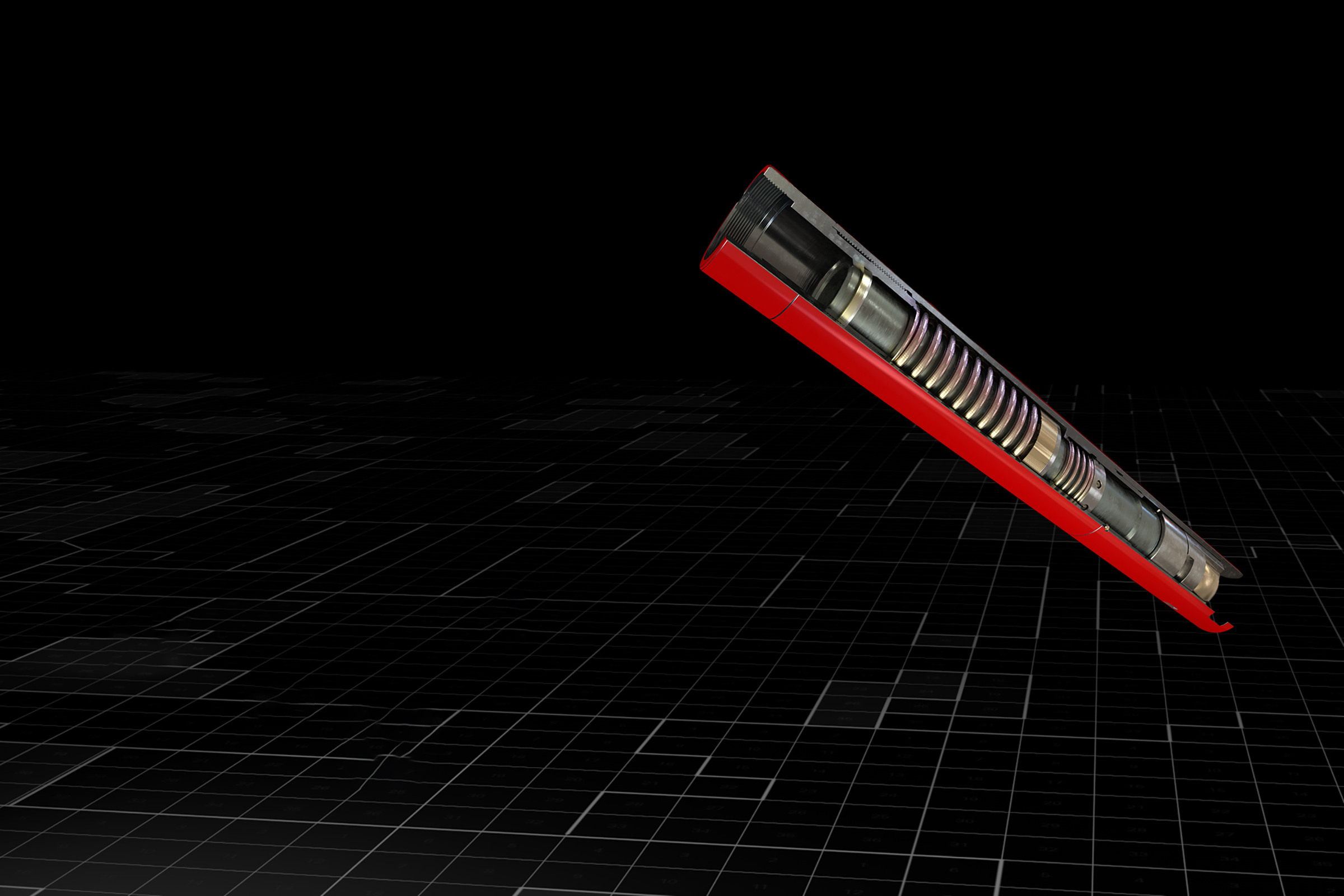

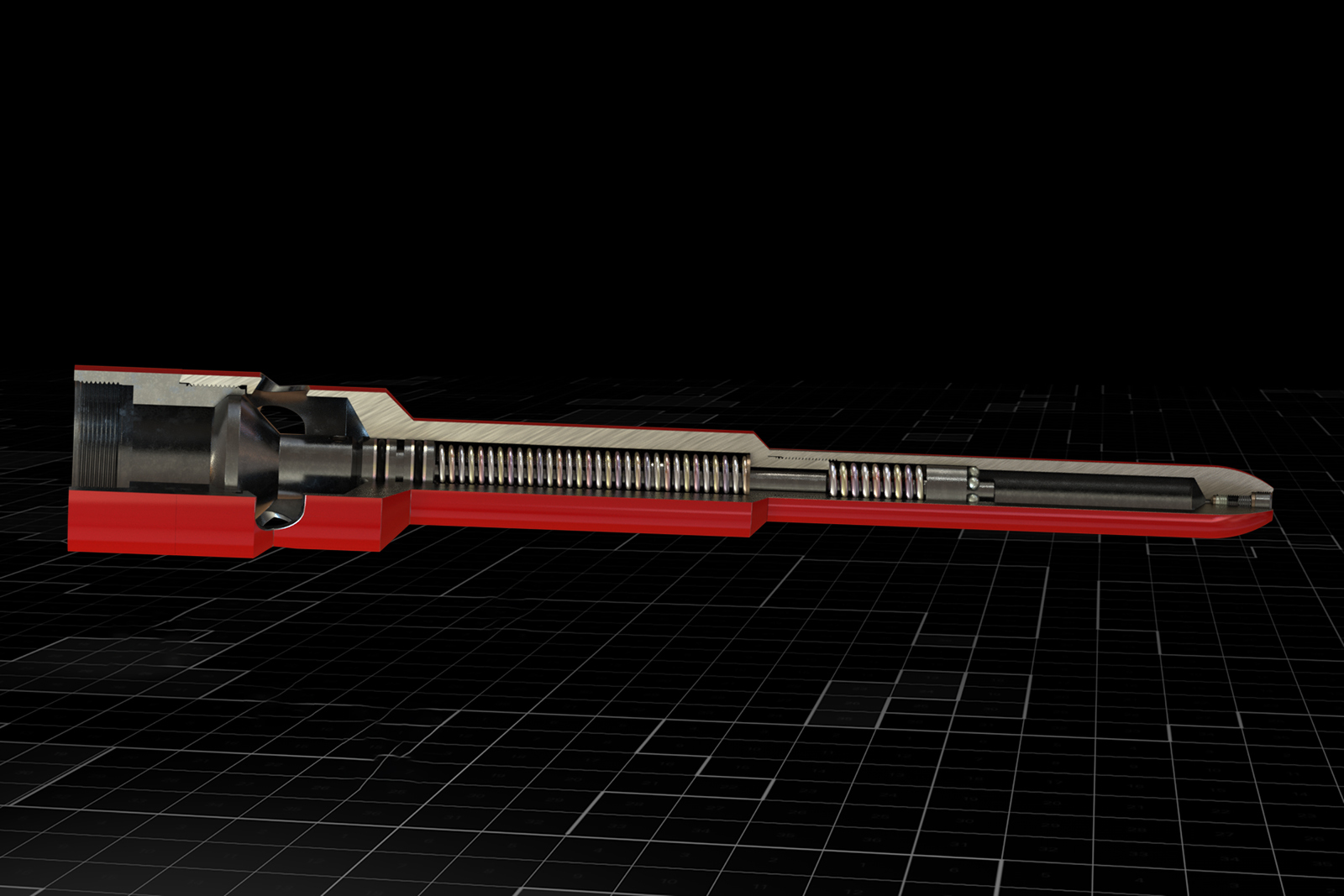

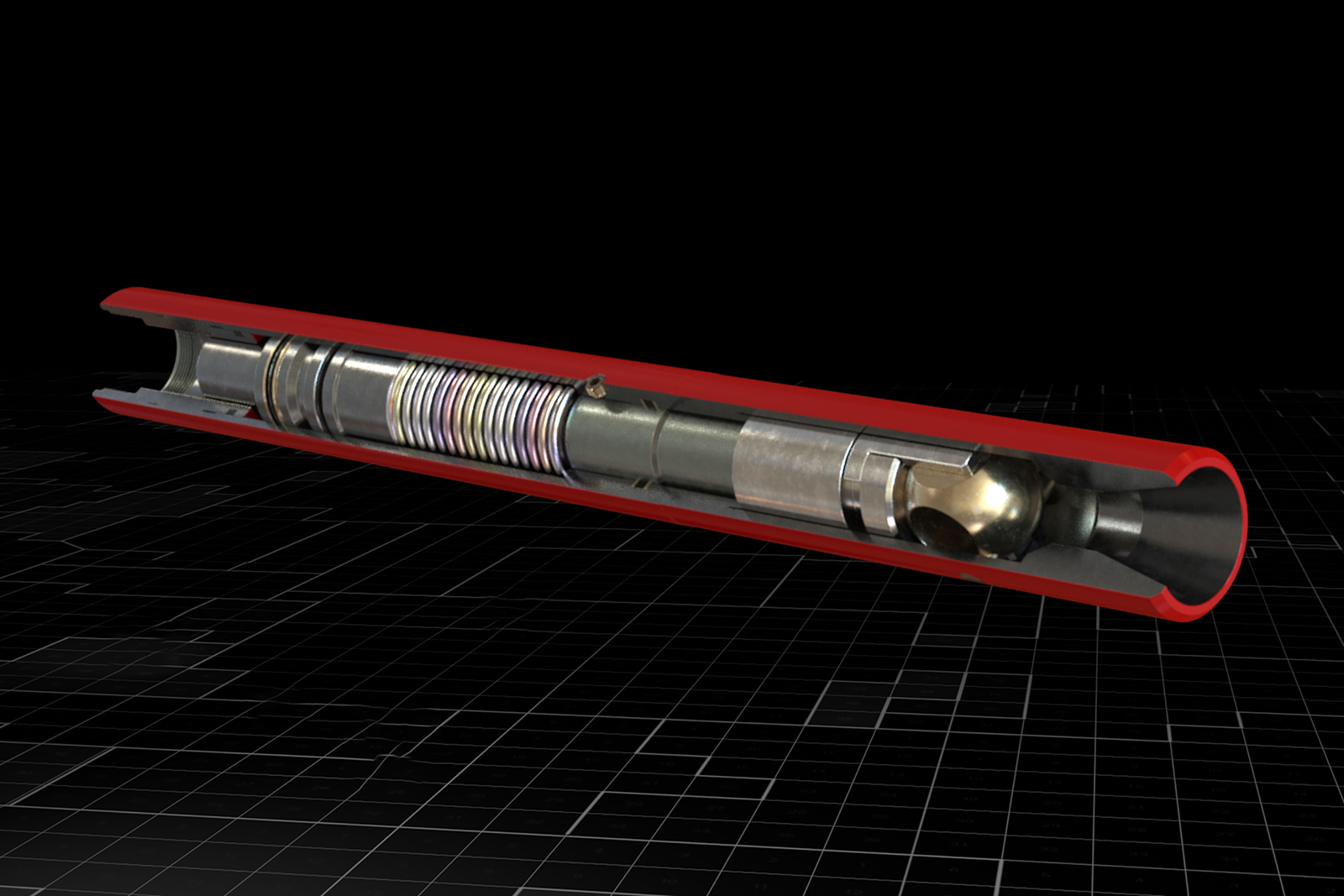

Storm Choke™ J safety valves are velocity-type, wireline- retrievable valves that are normally opened, direct-controlled valves. These valves operate on a spring-loaded, flow bean, pressure-differential principle and are designed for high-volume wells. A through-conduit design lessens turbulence and the possibility of sanding-up after closing. A detent mechanism provides a positive snap action closure at the valve’s predetermined disaster rate. A metal-to-metal ball and seat assembly is used for the primary closure mechanism seal.

When the valve is operating, a spring holds it off its seat until the well flow reaches a predetermined rate. When the pressure differential across the bean exceeds the spring force, as a result of a rupture in a flowline or the surface equipment, the valve is designed to close and shut the well. To reopen, the valve pressure must be fully equalized either by applying pressure in the tubing from the surface or by running a prong to allow equalization from below. When pressure is equalized, the spring will open the valve automatically.

Storm Choke K safety valves are ambient-type, wireline-retrievable valves with the largest flow area of all direct-controlled safety valves on the market. They are ideally suited for high-volume, low-pressure wells..

Storm Choke™ H safety valves are ambient-type, wireline-retrievable valves that are normally closed and pre-charged with a set dome pressure.

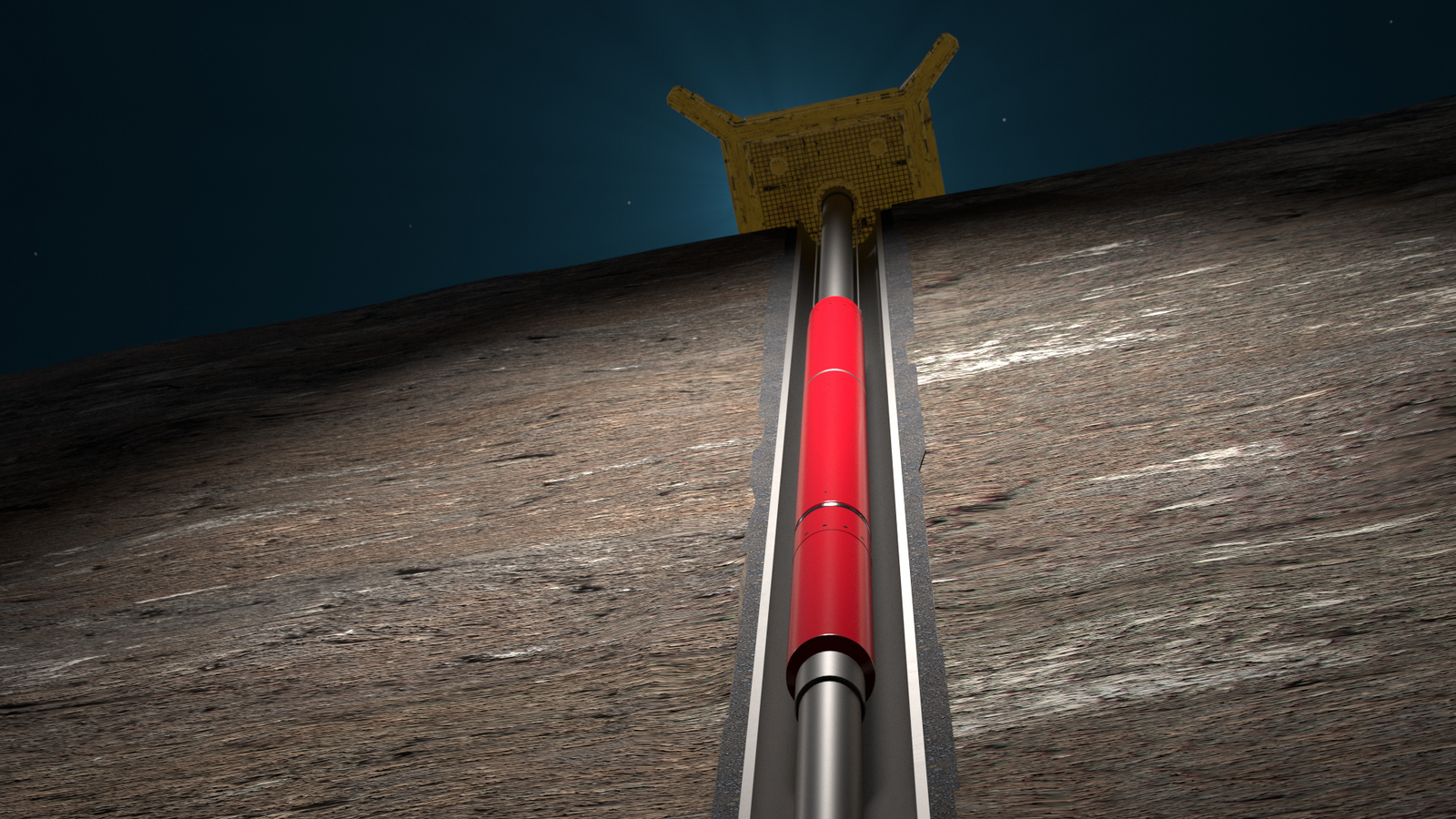

Halliburton tubing-retrievable and wireline-retrievable subsurface safety valves are a field-proven solution for operators.