Search

Search

Search

Search

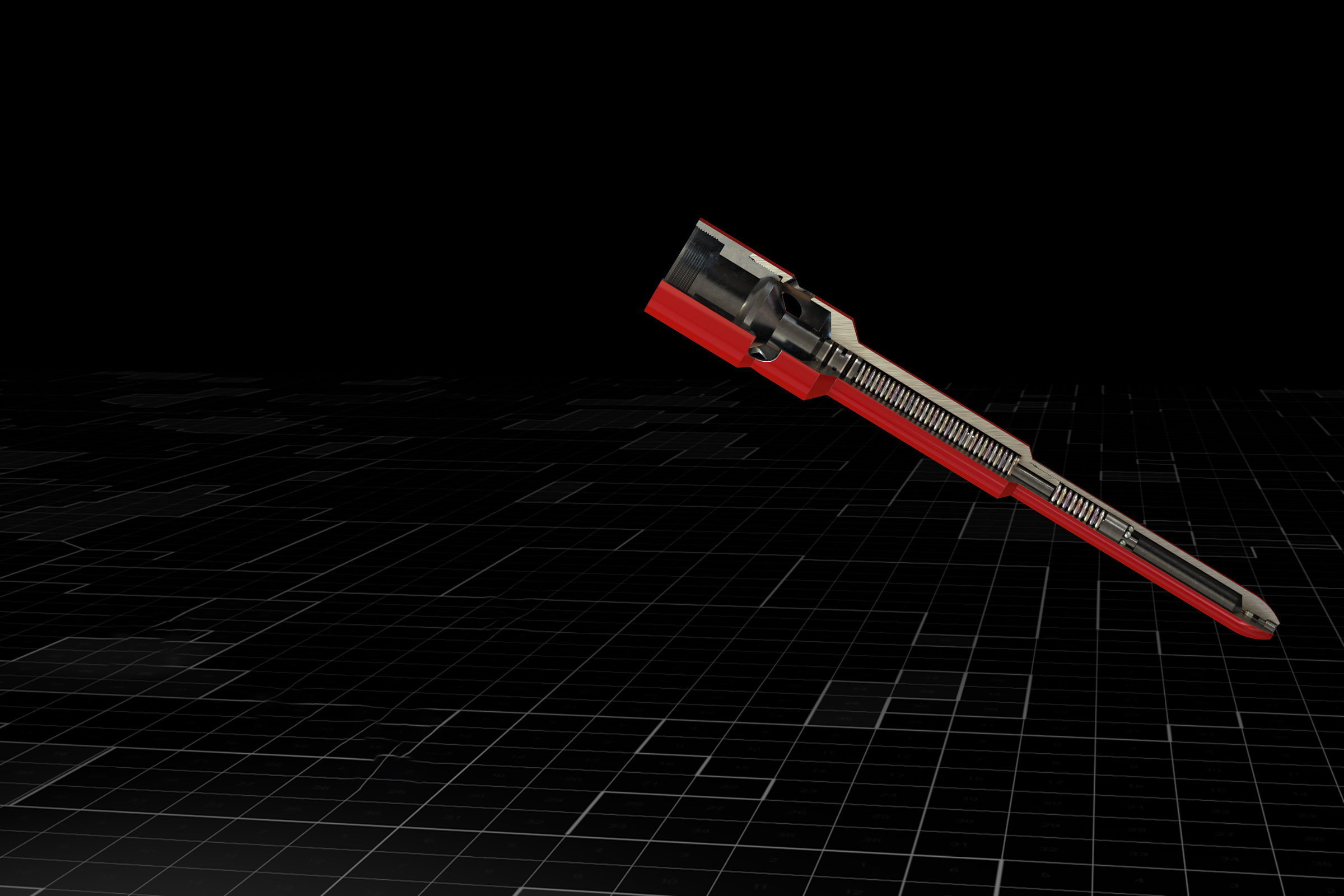

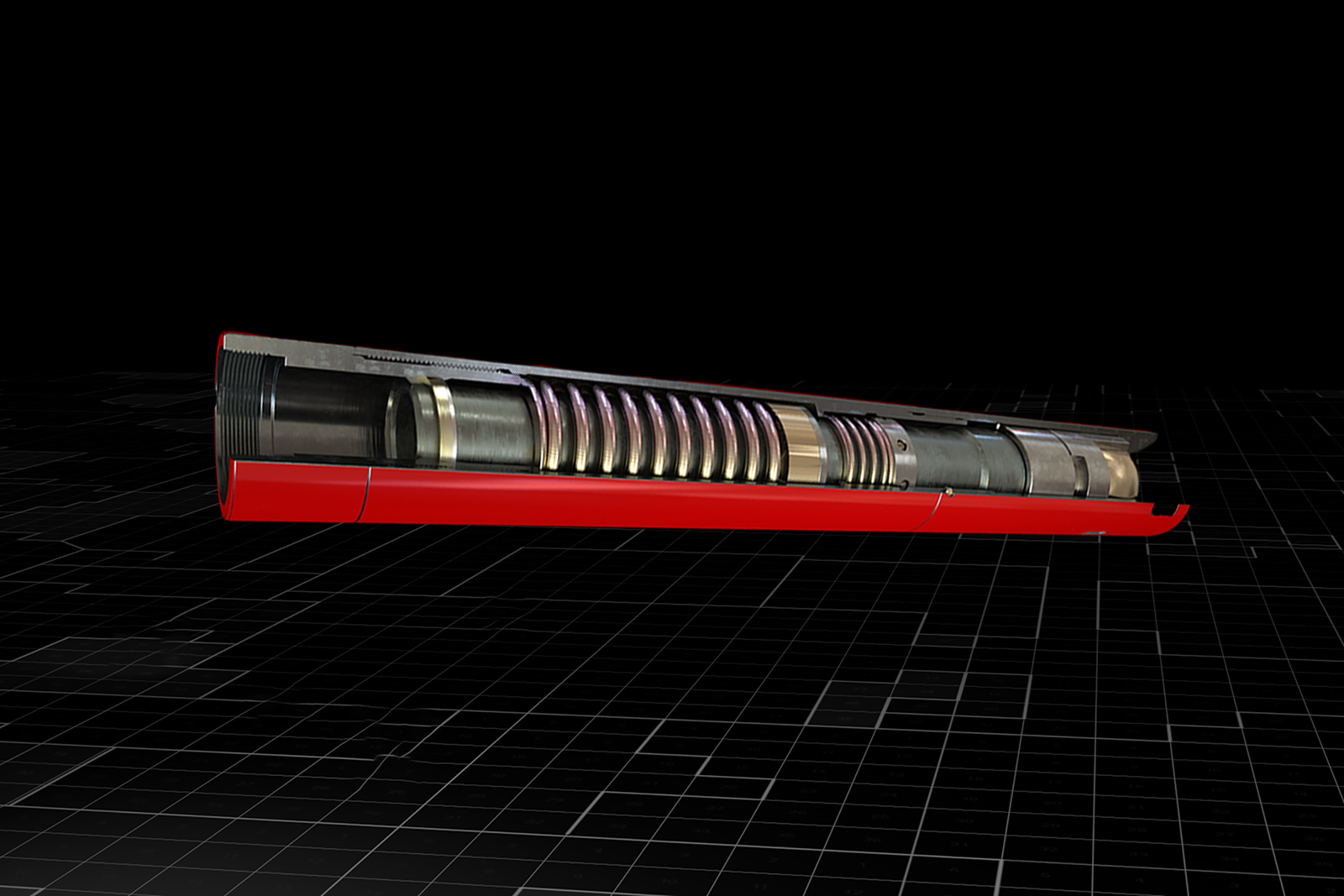

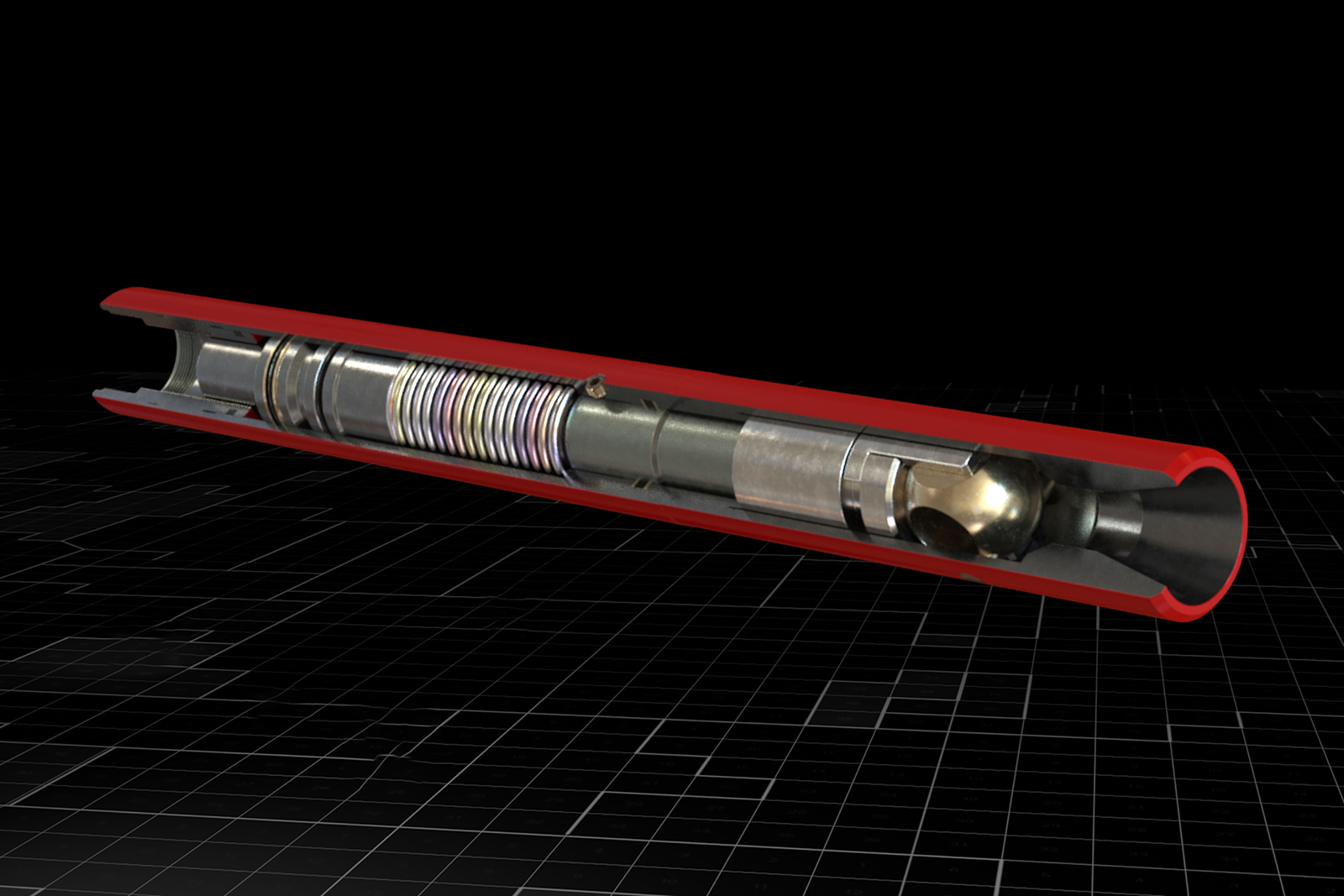

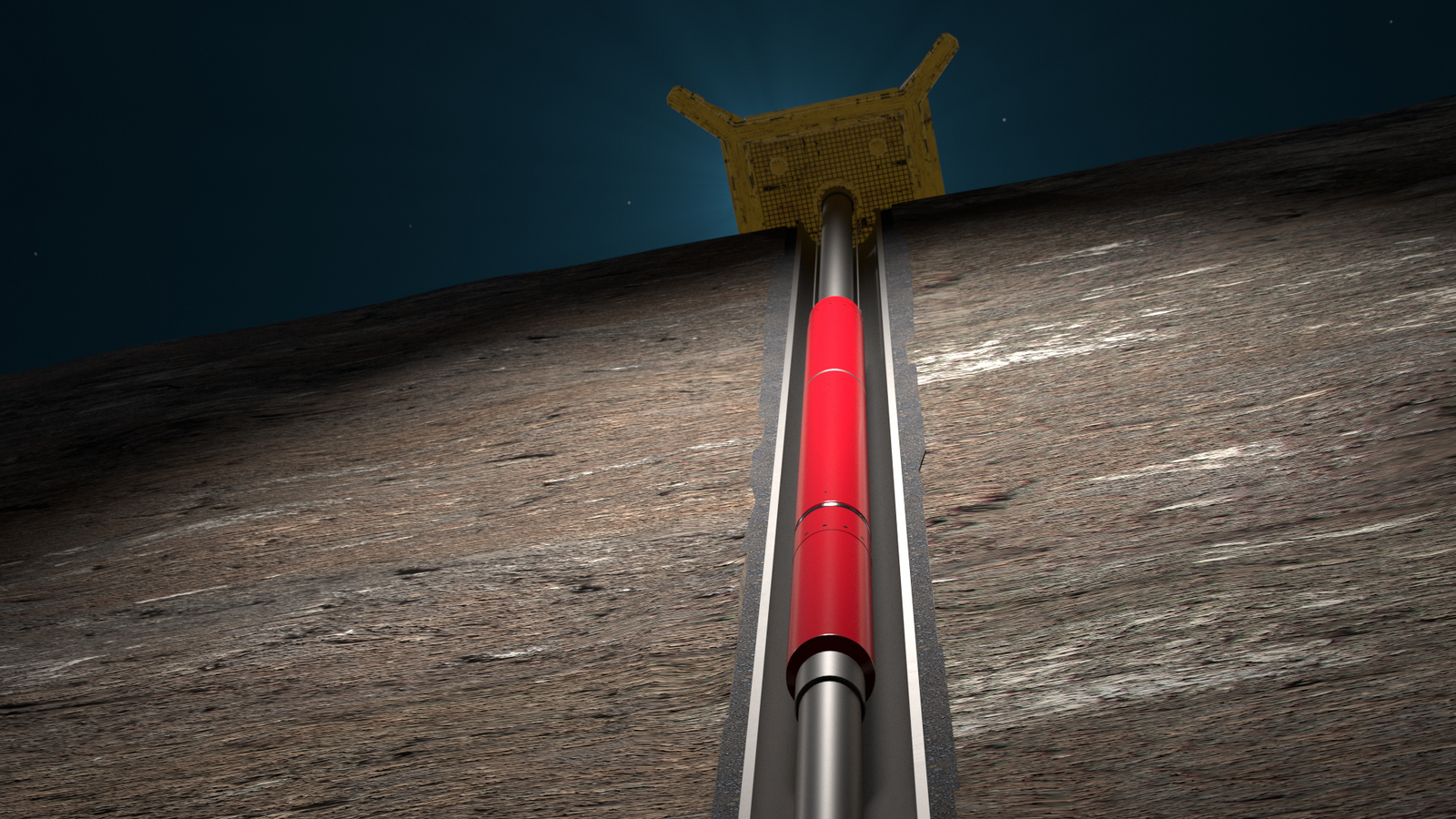

Storm Choke™ K safety valves are ambient-type, wireline-retrievable valves with the largest flow area of all direct-controlled safety valves on the market. They are ideally suited for high-volume, low-pressure wells. These valves are normally closed and pre-charged with a set dome pressure.

When the well flowing pressure drops below the predetermined dome-pressure charge, as a result of a rupture in flowline or surface equipment, the dome pressure and main valve spring close the valve, shutting in the well below the earth’s surface. This valve contains a detent mechanism to provide a positive snap-action closure at the valve’s predetermined disaster rate. Its bore is not restricted by a flow bean. The valve is designed to resist pressure surges. A metal-to-metal poppet valve and seat comprise the valve’s primary closure mechanism.

The K valve is ideal for protecting wells with declining bottomhole pressure. This valve closes in situations where a pressure decline would not activate a valve with a flow bean. To reopen the valve, the operator must fully equalize pressure either by applying pressure in the tubing from the surface or by an equalizing prong. The valve will reopen when the tubing pressure acting on the internal piston area overcomes the dome charge.

Storm Choke J safety valves are velocity-type, wireline- retrievable valves that are normally opened, direct-controlled valves.

Storm Choke™ H safety valves are ambient-type, wireline-retrievable valves that are normally closed and pre-charged with a set dome pressure.

Halliburton tubing-retrievable and wireline-retrievable subsurface safety valves are a field-proven solution for operators.