Search

Search

Search

Search

Deliver consistent performance and maintain continuity in critical subsea environments

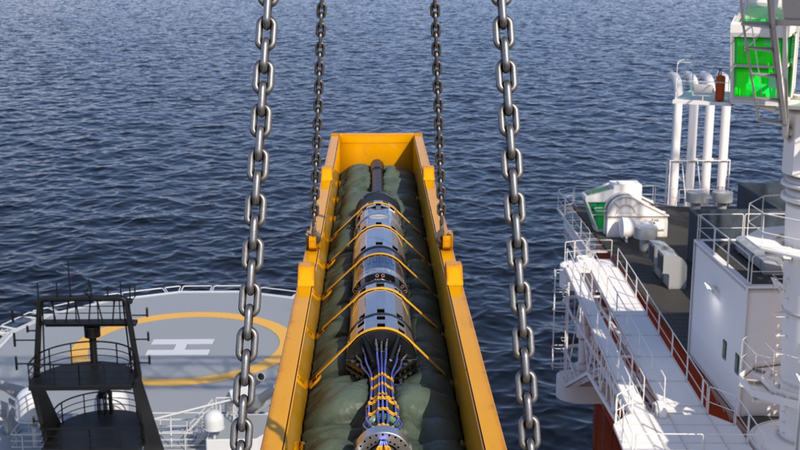

talk to an expertAchieve faster, safer subsea completions through precise orientation. The Optime tubing hanger orientation system (OTHOS) reduces rig time, improves safety, and simplifies offshore operations. It is a compact, gyro-guided design that supports vertical subsea tree applications without traditional orientation joints (THOJ) or complex blowout preventer (BOP) alignment systems. OTHOS helps ensure clockwise tubing hanger orientation regardless of BOP position.

Precision within ±1.5° prevents costly misalignment and keeps operations on schedule. Real-time heading and force data help operators to make confident decisions quickly. Operators cut mobilization time and reduce costs by removing unnecessary pre-run testing. A compact structure maximizes rig space and integrates seamlessly within the BOP for efficiency.

Simplify orientation and reduce red-zone exposure with a solution built for precision, safety, and efficiency. OTHOS provides accurate orientation that minimizes risk, streamline operations, and enables reliable subsea completions that meet performance goals.

| Operating limits | Design and manufacturing specification |

|---|---|

| Max working pressure (Internal) | 10,000 psi / 690 bar |

| Max working pressure (External) | 2,173 psi / 150 bar |

| Service temperature | 23–158°F / -5–70°C |

| Torsion capacity (THOP) | 18,500 lbf-ft / 25 kNm |

| Nominal orientation capacity OTHOS actuator | 18,500 lbf-ft / 25 kNm |

| Tubing hanger orientation accuracy | Typically, within +-1.5 degrees for final TH-orientation |

| Max working pressure (Internal) | 10,000 psi / 690 bar |

| Weight OTHOS main module | 1,600 lb / 730 kg |

| Length OTHOS main module | 43.5 in. / 1,104 mm |

| Outer diameter | 18.62 in. / 473 mm |

| Inner diameter | 4 in. / 101.6mm (ISO 13628-7 drift class 3a) |

Connections |

|

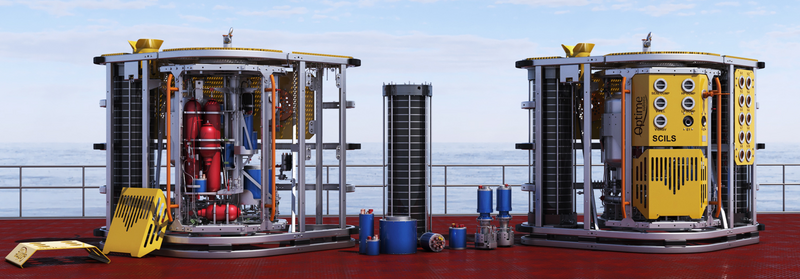

Halliburton offers innovative subsea safety systems for applications in completion and intervention operations.

eROCS removes traditional umbilicals and hydraulic power units (HPUs) to help reduce rig time, minimize red zone exposure, and optimize offshore efficiency

Minimize complexity and maximize flexibility with umbilical-less subsea tubing hanger installation systems

Industry first, field-proven closed-loop subsea controls unit complete with redundant subsea pumps, control modules, and a hydraulic reservoir